Non woven fabric slitting machine is a hot category in SUNTECH products, for producing steadily with top quality in high-demanding industries.

Filterability is quite crucial in the fields that have strict requirements of medical usage, such as medical protection. For example, the face masks used in medical and surgical procedures, need materials that are highly bacterial and virus filterable.

SUNTECH meltblown lines enable you to become a a trusted and sought-after supplier in the market because of the excellent quality and production stability of our non woven fabric slitting machine.

Exceptional Filtration Capacity(Optional Electricity Treatment to the Water)

Using electric treatment non woven fabric slitting machine is feasible to produce material with outstanding filterability and filterability. As an alternative, we also offer water electric treatment services (electret liquid system including spunlace elextet).

When pure water and meltblown fabric come into contact, electric charges are generated. After going through the spunlace electrostatic electret process, the material acquires characteristics such as high adsorption capacity, low resistence, and extreme filterability, which are in high demand in markets such as the filtration and pharmaceutical industries, among others.

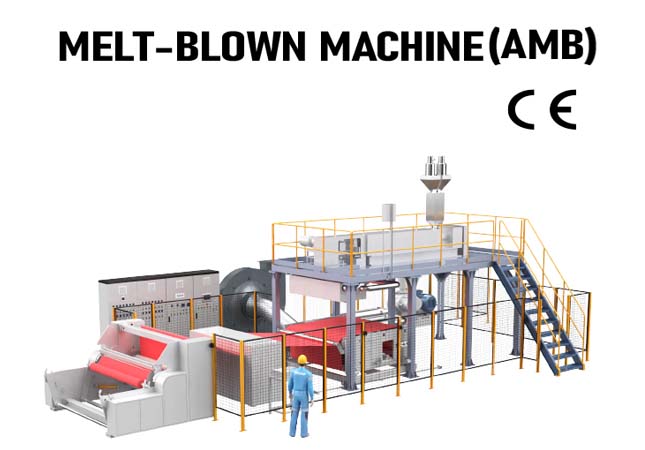

Extremely High-Quality Products to Ensure European Compliance

Because all of the non woven fabric slitting machine in the series have completed European compliance testing and have been approved, the non woven fabric slitting machine lines are very dependable and cost effective. In terms of product quality and safety, there are no issues, and this distinguishes you as a reliable supplier in the marketplace.

Simple Getting in and Out Process

Because of the simplicity with which our non woven fabric slitting machine machine manufacturing lines can be installed and the high level of automation they provide, you may enter the market, commence production, and acquire market share in as little as 10 to 15 days.

Make certain that the production is both stable and safe at the same time, and with our meltblown production lines, you can expect a constant high output and materials of the finest quality for applications like as filtration and pharmaceutical making.

SUNTECH Non-Woven Machine Specifications are Available Online

Visit this site if you're interested in learning more about the SUNTECH research initiative.

SUNTECH provides non woven fabric slitting machine/premium meltblown machines to produce high quality meltblown nonwovens.

It's widely applied in filtration and medical fields.

·Excellent filterability and barrier properties

·Strong stability with considerable productivity

·Easily enter easily run.

In specific industries like medical protection, there are ultra-strict standards for filterability. For instance, medical and surgical face mask requires the material must meet top-class filterability for bacteria and viruses. With our meltblown lines, you are worry free about quality and production stability, which makes you a reliable and sought-after supplier in the market quickly.

You May Read the SUNTECH Global Client Testimonials That Have Been Submitted.

Since its founding in 1976, Indonesia's most popular personal care brand, PT SOFTEX INDONESIA, has established itself as an industry standard.

Since its start in 1995, Zaimella has maintained a strong presence in the health and hygiene industry worldwide. It has grown to become one of Ecuador's most well-known personal care products companies in recent years.

Athens Stock Exchange listed shares in Thrace non woven machine& Geosynthetics SA in 1995, which took over all of Thrace Plastics' Technical Fabrics activities, which were created in 2010. The company was acquired by Thrace Plastics in 2010, which was renamed Thrace Nonwoven & Geosynthetics S.A. in 2015. Thrace NG manufactures a wide range of PP technical textiles and fibers for a variety of applications.

JSC Komitex is a Russian manufacturer of nonwovens and synthetic fibers.

The company was established in 1979 and now has around 1000 workers. There is a large variety of "dry method" nonwoven material manufacturing processes available at the company.

SUNTECH is always here to provide you with the best service and high quality textile and hygiene production lines.