As the global economic development has entered a new normal, the textile industry has seen an upsurge of "machine substitutions" that replace manual labor with automated and intelligent equipment. What has this craze brought to the industry? What is the problem? Is there any trend change in the workforce of the textile industry?

The textile economy has experienced 30 years of rapid development and is overly dependent on cheap human resources and abundant natural resources. With the continuous rise of labor costs in various countries and the escalation of resource problems, many textile orders in many countries have been forced to flow into lower labor costs. In Southeast Asian countries, the development of the textile industry is in trouble. With the disappearance of the demographic dividend and the increase in production costs, the new generation of textile workers pay more attention to their own rights. The textile manufacturing industry is facing the problem of transformation and upgrading, and intelligent development has become a trend.

The status quo of low-end products with low technical content, low added value, high labor cost, and low production efficiency no longer meets the current market needs and does not meet the future development of enterprises. The transformation and upgrading of textile machinery products is the general trend. The direction of industrial transformation is undoubtedly to achieve transformation and upgrading through technological progress and improvement of labor quality. Enterprises use mechanization and intelligent applications to improve production efficiency, increase benefits, and catch up with or exceed the increase in production costs. This is the meaning of transformation and upgrading, and "machine substitution" is a way.(try suntech Loom)

Difficult recruitment and expensive labor force the textile industry to "substitute machines"

The traditional textile industry is a labor-intensive industry. With the gradual disappearance of the demographic dividend, transformation and upgrading are urgent. Mechanization, automation, and intelligence have become effective ways to transform traditional industries, promote industrial transformation and upgrading, reduce staff to increase efficiency, and ease recruitment difficulties. This has also opened the curtain of "machine substitution" in the textile industry.

The report shows that rising labor costs and long-term structural shortage of labor in the industry have become one of the main reasons for the "machine substitution" in the textile industry.

In recent years, the growth rate of labor compensation has been accelerating. Enterprises have to raise the wages of employees 1-2 times a year, and enterprises obviously feel the pressure of employment is increasing. The development of the textile industry requires a large number of textile technical workers and skilled personnel, and textile enterprises generally face the dilemma of "labor shortage". At the same time, due to the high intensity of work in the textile industry, the mobility of employees is also high, especially young workers born in the 85s and 90s are reluctant to engage in monotonous, repetitive, and labor-intensive types of work. The frontline workers cannot receive effective supplements, which also makes many textile workers. The long-term lack of work for enterprises has forced them to use "machines for people". Take some textile companies in southern Jiangsu as an example, the companies face a shortage of about 10% every year.

At the same time, the industrial upgrading of the textile industry and the realization of high-quality development have created demand for intelligent manufacturing, and "machine substitution" has become a general trend. The survey shows that the quality of textiles is the competitiveness of enterprises, and the current development of textile quality is not optimistic. The instability of quality not only exists between different enterprises and different regions, but also exists in different batches of products within the enterprise. In between, it directly affects the market competitiveness of the product. In terms of promoting stable product quality and achieving high-quality development, intelligent robot production has incomparable advantages over manual production.

Due to labor costs and the impact of the Trans-Pacific Partnership (TPP), manufacturing powers such as Europe and the United States have shifted their focus to India, Vietnam, Bangladesh, Pakistan and other countries. Whether it is human capital, equipment or technology, Chinese textiles suffer Challenges to Southeast Asian countries. At the same time, even though many companies have introduced advanced foreign equipment, they still cannot change the relative technological backwardness of the industry. Therefore, "machine substitution" is imperative.

"Machine Substitution" for the textile industry to save energy and increase efficiency

The necessity and urgency of "machine substitution" in various industries are very prominent:

1. Cotton spinning industry. Large-scale technical transformation of blowing-carding unit and simple blowing-carding unit, high-efficiency and coarse, high-efficiency compact yarn long car, automatic winder, etc., has reached a new level of yarn quality indicators, average labor per 10,000 spindles, and energy saving. Especially the application of smart spinning doffing machine can greatly reduce the labor intensity of spinning workers, and the labor can be reduced by more than 40%. Taking the Changyuan Textile Company in Changle City, Fujian Province as an example, the original 10 spinning workshops were technically transformed and fully automated production lines were introduced. The number of workers was reduced from 504 to 317, and the monthly salary per capita increased by 1,000 yuan.

2. Chemical fiber industry. Through intelligent technological transformations such as flexible technology, energy saving and consumption reduction, the product differentiation level, quality performance and production efficiency have been significantly improved, and the number of labors has been greatly reduced. Take Fujian Baihong Group as an example. After the implementation of "machine substitution", the automatic doffing process reduces labor by 70%, and the automatic packaging process reduces labor by 80%; the cost of automatic packaging equipment renewal can be recovered in 3 to 4 years.

3. Functional textiles. The company has introduced a large number of high-performance automatic warp knitting machines, flat knitting machines, large circular knitting machines and supporting finishing equipment to develop all kinds of functional knitted fabric products for clothing, shoe materials, home textiles, and industrial use, adapting to the trend of domestic and foreign market demand. Taking Fujian Jinjiang Huayu Weaving Co., Ltd. as an example, 400 automatic warp knitting machines were introduced at one time, and the number of lathes was reduced from more than 800 to more than 200; the per capita management of 1 or 2 machines was upgraded to 5 machines per capita. ; Monthly wages have increased substantially from about 4,000 yuan per capita, and the monthly wages of the best skilled workers can reach nearly 10,000 yuan.

4. Footwear manufacturing. Pay attention to the improvement of design concepts and intelligent manufacturing, the function, art, and fashion design of clothing have been continuously strengthened, and the design, sewing processing and finishing level have made significant progress. Advantageous enterprises such as Qipai, Septwolves, Jiumuwang, and Jinba use robots to replace manual spreading and implement logistics process automation, which greatly reduces labor intensity and improves production efficiency.

5. Printing and dyeing industry. From the experience of advanced regions, after the implementation of "machine substitution" in printing and dyeing enterprises, the water consumption per 10,000 yuan of industrial value added by the company will drop by more than 15%, energy consumption by more than 17%, industrial wastewater discharge by more than 10%, and water reuse The rate reached 52.7%, saving labor costs by nearly 60%.

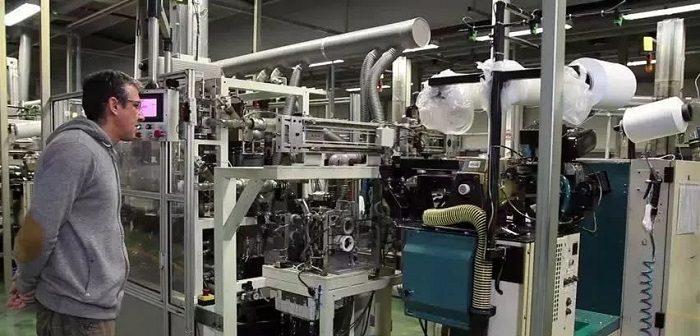

In textile production, the most important part of the workload is textiles. The artificial textiles in the past have been unable to meet the production needs. The emergence of intelligent rapier looms has solved the problem of slow textile speed, low efficiency and heavy manual dependence. problem.

Aiming at the problem of labor shortage, Suntech has developed and produced rapier looms with 50 years of design experience and technology precipitation, integrating various textile processes with intelligent, automated, and digital applications, allowing the links that originally required a large number of manual assembly lines to be replaced by machinery.

Suntech rapier looms can perform automatic machine inspection on the finished cloth, and solve the most difficult textile problem of most textile enterprises-cloth inspection. Enterprises do not need to hire additional inspectors with high wages and high technical requirements, which saves expensive inspection costs, and the inspection effect is better than manual inspection, with a low error rate, which optimizes the textile process and maximizes value, and reduces Labor, greatly reducing labor costs and improving production efficiency.

Customers who have used Suntech rapier looms are full of praise for this loom, which can be called artificial intelligence in the loom industry. According to statistics, this loom can save 50% of labor costs and 50% on average, and increase production by 50%. Efficiency, in addition to automatic fabric inspection, it can also be controlled by PLC, automatic weft seeking, servo electronic warp let-off, servo electronic take-up, so that every step of the textile is intelligent, and the production speed is greatly improved. Welcome to inquire.