In 2020, the world is affected by the covid-19. Europe and the United States are particularly serious. They are caught in long-term shutdowns and production. Some textile business orders are transferred to China, which indirectly stimulates the development of China's textile industry and China becomes the largest manufacturing country. The development of the textile industry is inseparable from textile machinery. With the development of the times, China's textile machinery is gradually entering the stage of intelligence, and manufacturing is gradually turning into "intelligent manufacturing."

Current status of the textile industry

In 2020, the industrial added value of China's textile enterprises fell by 2.6% year-on-year. Among them, the industrial added value of the textile industry increased by 0.7% year-on-year; the industrial added value of the chemical fiber manufacturing industry increased by 2.2% year-on-year; the industrial added value of the textile and apparel and apparel industries decreased by 9.0% year-on-year. Driven by the demand for anti-epidemic materials, the industrial added value of industrial textile companies in 2020 will increase by 54.1% year-on-year, and the output of non-woven fabrics will increase by 15.8% year-on-year.

In 2020, textile enterprises above designated size achieved operating income of 4.5191 billion yuan, a year-on-year decrease of 8.8%; realized total profits of 206.5 billion yuan, a year-on-year decrease of 6.4%.

In 2020, China's textile and apparel exports were US$291.2 billion, close to the best level in history, with a year-on-year increase of 9.6%. Among them, driven by the export of anti-epidemic materials, textile exports increased by 29.2% year-on-year; affected by the epidemic in major foreign markets, clothing exports fell by 6.4% year-on-year.

The status quo of the textile machinery industry

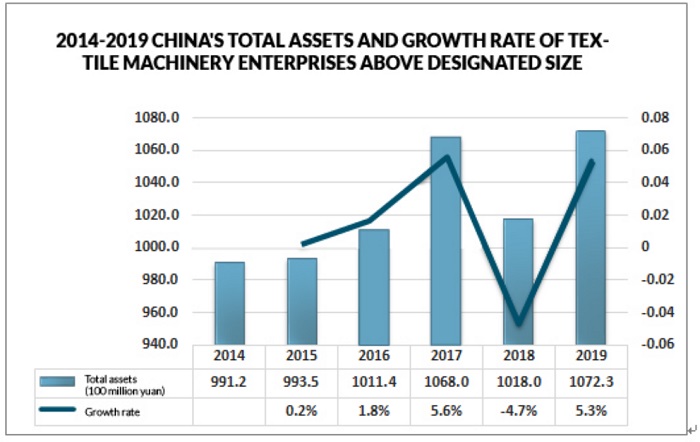

In 2019, the total assets of China's textile machinery enterprises above designated size were 107.23 billion yuan, a year-on-year increase of 5.3%.

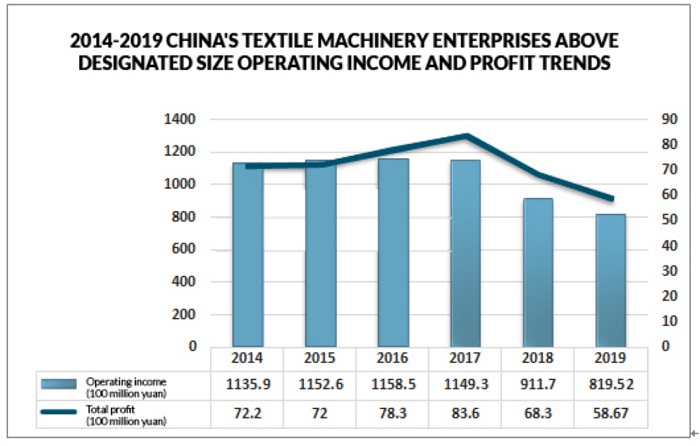

According to data from China Textile Machinery Association, in 2019, the operating income of China's textile machinery enterprises above designated size was 81.952 billion yuan, a year-on-year decrease of 10.1%; the total profit of China's textile machinery enterprises above designated size was 5.867 billion yuan, a year-on-year decrease of 14.1%.

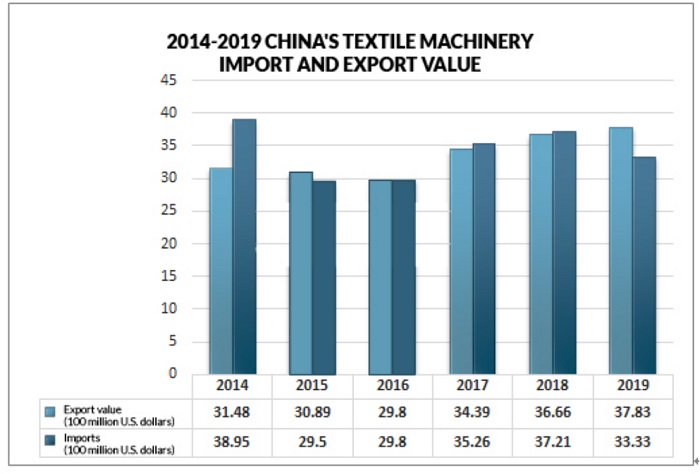

From the perspective of the import and export value of China's textile machinery industry, the import and export value of textile machinery has remained at around US$3-40 billion in recent years. In 2019, China's textile machinery export value was US$3.783 billion, an increase of 3.2% year-on-year; China's textile machinery import value was US$3.333 billion, a year-on-year decrease of 10.4%.

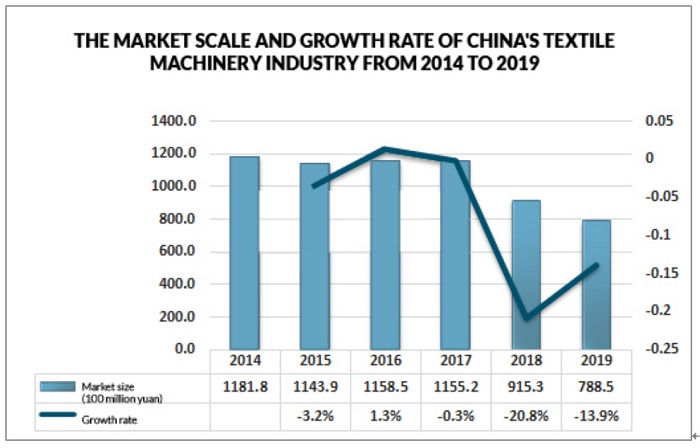

China's textile machinery manufacturing industry has become a pillar industry with a complete range of categories, meeting the needs of the textile industry and having independent R&D and innovation capabilities. In 2019, the market size of China's textile machinery industry was 78.85 billion yuan, a year-on-year decrease of 13.9%.

It can be seen that China’s textile industry still maintains rapid growth, and there is huge room for future development. This is due to the technological development and technological improvement of textile machinery. As an old textile machinery company, Suntech, after 50 years of technological precipitation and experience Technology is integrated into the research and development of intelligent equipment, and the design and production of intelligent mask machines, meltblown machines, spunbond non-woven machines, spunmelt non-woven machines, fabric inspection machines, packaging machines, fabric inspection packaging lines and other equipment have a good reputation in the world , Word of mouth is bursting, and the return rate is high.(try Suntech spunbond nonwoven machine)

Textile machinery classification

The main process of weaving is as follows: spinning machinery spins various natural and chemical fibers into yarn, weaving machinery weaves the yarn into cloth, printing and dyeing machinery dyes and finishes the cloth, and finally uses clothing machinery to make the fabric into clothing.

There are many types of textile machinery involved, and textile machinery companies generally can only produce some of them.

1. Spinning machinery

Spinning machinery is a textile machinery that spins various natural fibers (cotton, wool, hemp, silk, etc.) and chemical short fibers into yarns. Among spinning machinery in my country, cotton spinning machinery accounts for more than 60% of the market.

2. Weaving machinery

The weaving process includes processes such as weaving preparation, weaving and finishing.

Weaving machinery is a device that intersects the warp and weft that are arranged perpendicular to each other to form a fabric. In the weaving process, the weaving machine introduces the weft yarn into the opened warp yarn layer (consisting of several warp yarns of the same length arranged in parallel), so that the warp and weft are interwoven to form a fabric. This process is called "weft insertion". The weft insertion methods of weaving machinery are divided into shuttle weft insertion and shuttleless weft insertion. Weaving machinery is also divided into two categories: shuttle looms and shuttleless looms. The shuttle loom adopts the traditional weft insertion method. The shuttle introduces the weft yarn into the opened warp yarn layer. The shuttle is generally made of wood or composite material that is resistant to impact, abrasion, and toughness, and has a certain degree of elasticity; In the working process of the machine, the shuttle needs to be repeatedly projected to complete the weft insertion; due to the large size and heavy weight of the shuttle, the shuttle loom has large vibration, high noise, slow speed and low efficiency. The shuttleless loom replaces the shuttle with a small, light-weight weft inserter (such as air or water jets, rapier head) to insert weft; after the shuttleless loom was introduced to the market in the 1950s, its The advantages of light weight, low vibration, low noise, fast speed, and high weft insertion rate have continuously replaced shuttle looms. The shuttleless transformation of weaving machinery has become a trend in the global loom market. At present, the proportion of shuttleless looms in developed countries has reached more than 90%, while the proportion of shuttleless looms in my country is only about 50%. my country's shuttleless loom market has huge room for development. Shuttleless looms are divided into rapier looms, air jet looms, water jet looms, projectile looms, etc. according to the different weft insertion carriers.

3. Printing and Dyeing Machinery

The printing and dyeing process includes pre-printing and dyeing preparation, dyeing, printing and post-treatment processes.

Follow-up link of textile production and processing

After the textiles are produced, the most important thing is fabric inspection and packaging, which are important links related to textile quality and brand value-added. Since many textiles have defects after they are produced, and the number of defects determines the grade and quality of the textiles, which in turn affects the brand reputation and price, the fabric inspection is indispensable. fabric inspection machines have gradually replaced manual inspections with the advantages of high efficiency and low error rate, and have a place in the textile industry.

(Suntech fabric inspecting machine)

Although textiles that have undergone fabric inspection can be regarded as qualified products, they cannot be regarded as commodities. The important part of becoming a commodity is packaging. People rely on clothing, and beauty depends on packaging. The packaging machine not only makes textiles more compact and reduces the footprint, but also can beautify the look and feel, so that the textiles have a better appearance.

Traditional textile inspection generally uses manual inspection, but manual inspection has many problems:

1. The speed is slow, the output is low, and the efficiency is poor. Generally, the inspector can only detect about 200 defects per hour. If it exceeds this range, it is prone to miss inspection and misjudgment. However, functional and high-performance fiber fabrics are widely used in aerospace, aviation, military, navigation and other fields. Zero defects and zero leakage are required for fabrics, and manual inspection is difficult to meet high standards.

2. High requirements for inspectors. Manual fabric inspection has certain technical requirements and vision requirements for inspectors. Long-term concentrated vision can easily lead to eye fatigue, occupational diseases, and low labor intensity.

3. The error is high. Manual fabric inspection is restricted by the inspector's subjective consciousness, personality, environment, cognition and other factors, and the test results are difficult to be consistent, the difference is large, and the reproducibility and consistency are poor.

4. Consume labor. Relevant information shows that the general traditional loom 500 sets of three-shift system requires 2.5 cloth inspectors, 2.8 cloth repairers, and corresponding random inspection personnel and other auxiliary personnel. The labor cost is relatively high.

5. The width is small. Traditional manual inspection of fabrics can only inspect fabrics with a smaller width, which is not suitable for the width requirements of modern looms. If the width is expanded and reformed, it is necessary to reduce the speed and increase the load of the inspection work.

Suntech intelligent fabric inspection and packaging line fabric inspection machine overcomes the shortcomings of manual fabric inspection, integrates fabric inspection and packaging, and automatically completes fabric inspection and packaging. It is more convenient and has many advantages as follows:

1. Fully automatic. Suntech fabric inspection machine can detect fabric defects in online or offline conditions, determine the location of the defects, classify and score the defects according to their size, hazard, and degree of impact, and issue alarms for serious defects or implement measures such as shutting down or opening and cutting.

2. Suitable for all kinds of fabrics. The Suntech fabric inspection machine can detect the basic organization and change organization of fabrics, including cotton, linen, silk, wool, chemical fiber and blended yarn fabrics and other fabric raw materials.

3. High pass rate. The production volume of Suntech fabric inspection system equipment is significantly higher than that of manual fabric inspection, or even several times higher. The accuracy rate of automatic fabric inspection fabric defect detection reaches more than 95%, which is much higher than manual fabric inspection, the rate of missed inspections and errors. The judgment rate is less than 5%, which is much lower than manual fabric inspection.

4. Fast speed, adjustable speed. The production speed of Suntech automatic fabric inspection is generally up to 120m/min or more, up to 300m/min. The inspection speed can be adjusted according to the needs. The actual inspection speed is related to the machine width and defects.

5.Automatic length check. Suntech cloth inspecting machine is equipped with a length counting device, and it can also check the length of sewing material at the same time. The traditional manual inspection of cloth requires visual inspection of whether there are defects on the surface of the sewing material. If there are defects such as yarn defects, weaving defects, stains or color differences, immediately mark the edges of the sewing material for repair or removal. Suntech fabric inspection machine saves these troubles.

Suntech, as an old-brand fabric inspection machine manufacturer, has 50 years of technical precipitation and equipment manufacturing experience.With more than 4,500 customers and 10,000 machine installation cases around the world, we specialize in the production of fabric inspection machines and fabric inspection packaging lines (including fabric inspection machines and packaging machines). Manual, semi-automatic and automatic fabric inspection machines can be customized according to user needs 13-month warranty and free accessories such as optoelectronics, digital length meter, etc. are welcome to inquire.