As labor costs continue to rise, more and more companies are facing difficulties in recruiting workers, and robots have become the general trend. Industrial vehicle intelligence (AGV) is also gradually seizing the traditional forklift market. AGV fulfills the humanized and diversified needs of customers with high efficiency and low cost, and plays a very important role in the internal logistics of smart warehousing and smart factories.

AGV is different from traditional forklifts in that it does not need to be driven manually, and has the characteristics of intelligence, flexibility, flexibility, low cost, high efficiency, and safe operation. It can solve the situation that traditional forklifts are difficult to operate in bad weather and dangerous environments, and can reduce exhaust gas and noise. It can also meet the individual needs of enterprises and have a very broad market prospect.

AGV market analysis

According to the statistics of the New Strategic Robot Industry Research Institute, since 2015, the annual sales growth rate of China's forklift AGV robots has maintained more than 50%. The enthusiastic market demand has prompted the continuous emergence of outstanding companies in this segment.

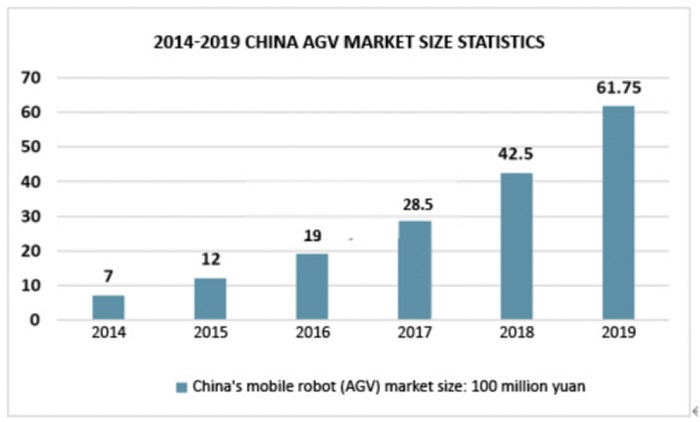

In 2019, China's mobile robot (AGV) market reached 6.175 billion yuan (including industrial AMR), a year-on-year increase of 45.29%. The compound growth rate of China's mobile robot (AGV) market from 2014 to 2019 was 54.56%, and the growth rate in recent years The improvement also reflects that my country's manufacturing industry has achieved considerable results in the process of intelligent development.

2015-2019 China Mobile Robot (AGV) Market Scale

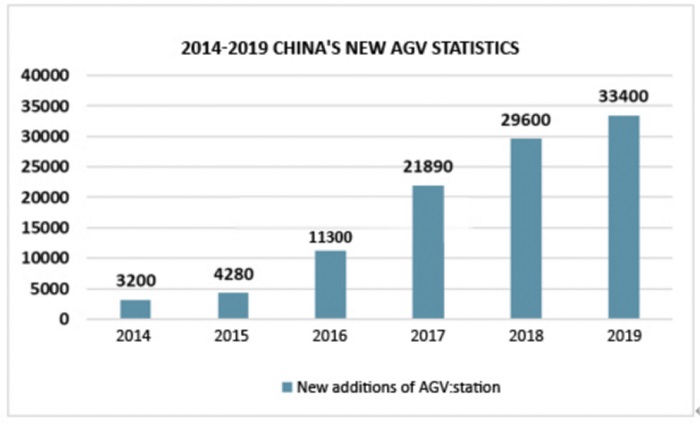

Beginning in 2016, the growth rate of new additions of mobile robots (AGV) has increased significantly. As of 2019, all categories of AGV robots have added 33,400 units, a year-on-year increase of 12.84%. From 2014 to 2019, the compound growth rate of new mobile robots (AGV) in China was 59.85%.

Trend chart of China's new AGV robots from 2014 to 2019

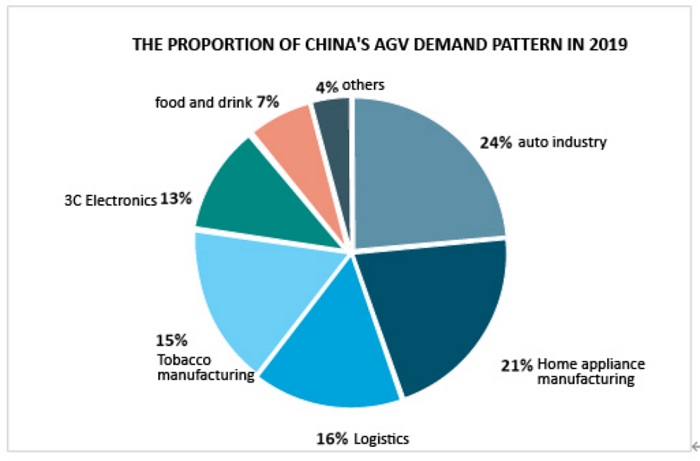

At present, the application of AGV robots in China is mainly concentrated in the fields of manufacturing, logistics and transportation and inspection. The automotive industry, home appliance manufacturing and other fields are currently the main domestic AGV demand markets. The two major industries have stable demand for AGV, but the requirements for intelligent automation of products are getting higher and higher.

However, from the perspective of the development trend of the top three application fields, the scale of production and sales of China's automobile manufacturing has begun to decline. Although the increase in AGV penetration is conducive to increasing the market scale of AGVs in the automotive industry, it is affected by the new market space of the automotive industry. The future development prospects of AGV robots in the automotive industry are weaker than those in the home appliance manufacturing and logistics industries.

At the beginning of 2020, due to the impact of the new crown virus epidemic, the domestic manufacturing and logistics and transportation industries have been suspended and production, and the mobile robot (AGV) industry has been affected to a certain extent. Especially in the first quarter, a small number of companies are facing survival pressure. Later, with the effective control of the domestic epidemic and the acceleration of the resumption of work and production, the domestic AGV industry has gradually recovered. Companies with brand effects and forward-looking technologies are expected to accelerate their capture of the downstream recovery market through technological advantages and mergers and acquisitions, and expand corporate profits.

At present, the epidemic has gradually subsided. With the exception of China, which has long since emerged from the epidemic, many countries around the world have slowly resumed production, and the AGV market has rebounded sharply. Various industries will involve transportation and warehousing problems, and labor costs will only become higher and higher. In the future, the proportion of AGV use will be further increased. In order to solve the world’s warehousing and transportation problems and improve production efficiency, Suntech has 50 years of technical precipitation and design experience , The AGV developed and produced can adapt to the needs of all walks of life. It is light in weight and heavy in load. It adopts an intelligent electronic control system, interactive interface and safety system to keep abreast of the AGV running dynamics, automatically avoid obstacles, safe and controllable, powered by lithium batteries, Online automatic fast charging, laser guidance, support for manual driving or wireless control, suitable for various transportation scenarios, please inquire for details.

Why should we use AGV?

AGV Robots AGV Robots - Autocraft, Inc.AGV robots offer their users many benefits. First, using AGV robots, manufacturers can save time and money. During auto parts assembly, for example, AGV robots can put together large parts much more efficiently than humans. They can even make tooling switches without assistance. Not only that, but they have no learning curve. Once programmed, they will perform their duties perfectly. Also, their programming tends to make them more precise and eliminates human error. Their operation also takes people out of harm’s way. For loading and unloading applications, AGV robots offer greater mobility and high strength. Plus, once again, they eliminate the need to people in high stress or high risk situations. Another advantage of AGV robots is the fact that they are easier to set up that regular AGVs, as they require fewer physical markers and guides. Finally, AGV robots are adaptable. If your application changes, you can simply change their programming in accordance with it.(try Suntech AGV)

AGV systems

AGV systems and vehicles perform transportation operations within a factory or processing plant according to a preprogrammed route, or according to internal navigation which adjusts the route. AGV systems are used in almost all industries including aerospace, food processing, general manufacturing, newspaper and mail, storage and automotive. Fixed path systems use a physical guidance path such an embedded wire, a colored tape strip or a magnetic line which is laid out in the route the vehicle is to travel through the warehouse or manufacturing space. The AGV uses an antenna and frequencies to ensure it follows the correct route. These systems are becoming less popular due to the inflexibility of a set route.

More commonly, AGV systems use computer controlled vehicles which have internal navigation systems and are able to adjust their routes based on expected traffic and obstructions. The systems can be complicated and require high levels of input and preprogramming, and usually will need to be monitored to ensure smooth operation.

Able to range in size from light load automatic guided vehicles for small parts and light assembly processes, to material handling robots which are able to assist with electronic fabrication and parts kitting. Other guided vehicles include pallet trucks which are able to move loads too cumbersome for efficient manual transportation. There are a number of advantages to including an AGV system in a manufacturing plant. They are efficient and dependable and are able to cut back on time and manual labor which can greatly slow down turnaround times in factory processes. Self propelled vehicles are able to fit into small spaces, to work in the same spaces as people, even in aisles, and with the use of the latest technology are able to efficiently adapt to changing floor conditions, ensuring the processes are not stalled. Furthermore, AGVs are able to work around the clock in processes which may not require much operator supervision, further increasing output. Although it might be a large initial investment, manufacturing productivity and operation flow are greatly improved with the addition of well-suited guided vehicle systems, making the high investment worthwhile over time.

Suntech is a worldwide leader in AGV technology. We have made it our goal to manufacture and fabricate the automated guided vehicles that our customers around the world rely on. We build turnkey systems that include concept, design, assembly, integration, software and installation. Our advanced AGV systems can drastically increase productivity, flexibility, and allow for full control of logistics in the most complex and dynamic applications.

The AGV systems we provide are applicable to multiple industries that we serve, and we aim to use listening, experience, and curiosity to provide products that satisfy any requirement.Our talented teams of designers and engineers will work with you in order to come up with a product that is as customized as you need it to be.

If designed to move around a facility, AGV robots often work using trackless navigation, meaning that they use sensors, lasers and software to figure out their surroundings and move accordingly. In contrast, regular AGVs run on fixed paths, such as those defined by embedded wires or magnetic tape. Manufacturers base the design of an AGV robot on its application. To make AGV robots even more useful, suntech offer a wide variety of customization options and include accessories like contact bumpers.

AGV Key Markets

With more than 30 years of experience in material handling and logistic solutions, our AGV systems are used globally across diverse markets. Our engineering, project management, and service teams have the industry expertise to meet your specific and time-sensitive demands.

1.Healthcare

Given the need for efficient, accurate, and on-time delivery of medicines, food, linens, and other critical supplies in the complex and fast-paced modern healthcare infrastructure, we provide optimized solutions that reduce labor expenditure while increasing reliability and flexibility.

With AGVs handling logistics, employees in healthcare settings can concentrate on patient care.

2.Automotive

We provide state-of-the-art automated processes with 24/7 delivery of parts and supplies to production lines, ensuring automotive manufacturers maintain a competitive advantage in this truly globalized market.

Our AGV systems provide strategic solutions for automating mission-critical operations that go beyond simply replacing conventional fork trucks.

AGVs can be used throughout automotive production processes to increase flexibility while reducing risks and related labor costs.

3.Warehouse Automation

In this highly competitive marketplace, we equip you with state-of-the-art warehouse automation and the ability to accurately deliver expedited orders. Our logistics solutions enable you to meet quick turnaround demands for same-day or next-day deliveries.

Our scalable systems deliver increased picking performance and complete order-fulfillment control. This automation enables highly efficient operations while minimizing labor costs.

4.Pharmaceutical

Our AGV systems enable you to maintain complete traceability and meet regulatory standards by avoiding human errors in material handling and logistics. We deliver critical operational agility, integrated communications, and tracking and tracing capabilities imperative in today’s pharmaceutical facilities.

5.Metals and Heavy-Duty Applications

We help you stay competitive in the metals fabrication market as you strive to deliver higher-quality goods at lower prices and with continual production increases. Our heavy-load transport systems ensure you meet these challenges while delivering end products safely and efficiently.

6.Electronics and Plastics

Our AGV systems provide customizable logistic solutions for the raw, in-process, and finished electronics and plastics found in nearly every item manufactured today. These smart production systems are vertically integrated across the entire supply chain to support complex and capital-intensive automated environments.

Suntech AGV

Suntech has researched and compared various AGVs with 50 years of technical precipitation and design experience, and finally developed and produced the following four practical AGVs that meet the needs of most users:

1. Forklift AGV

The AGV is a forklift-type structure with light weight and large load. It adopts the latest electronic control system, which makes the whole vehicle more controllable and reliable in the whole series of processes of design, production, operation and maintenance.

2. Drum AGV

The AGV is mainly used in automated logistics conveyor lines in an industrial environment to complete the handling of goods between stations and stations, and between stations and warehouses. It is an important part of the future Industry 4.0 smart factory and can replace manual logistics. The complicated, difficult, dangerous and repetitive tasks encountered in the system.

The AGV is composed of a two-wheel differential sports chassis and a cargo business module. It is equipped with the latest hardware platform and software system, and realizes cargo handling based on autonomous navigation technology and sports chassis technology.

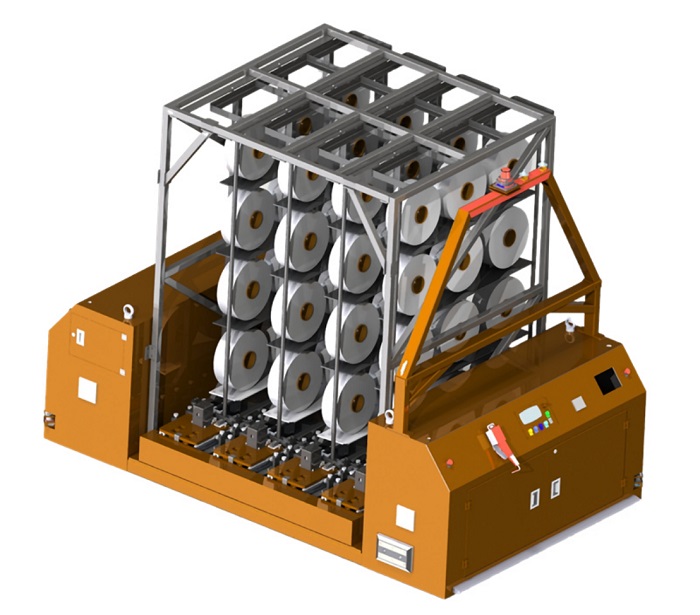

3. Two-way backpack AGV-1.5T

The AGV contains two parts: hardware and software. Main function: Realize the automatic docking and handling of materials in the automatic threading production line of the texturing workshop.

The AGV is a non-standard customized knapsack AGV. The automatic threading AGV part of the texturing workshop is composed of the AGV central management system and the non-standard customized unit loaded on the AGV. At the same time, the non-standard customized unit loaded on the AGV is composed of mechanical structure and electric The actuator, pneumatic actuator and other components.

.jpg)

4. Two-way backpack AGV-3.5T

The AGV contains two parts: hardware and software. Main function: to realize the automatic docking and handling of materials on the automatic silk production line in the texturing workshop.

The AGV is a non-standard customized backpack AGV. The automatic threading AGV part of the texturing workshop is composed of the AGV central management system and the non-standard customized unit mounted on the AGV. At the same time, the non-standard customized unit mounted on the AGV is composed of mechanical structure and electric The actuator, pneumatic actuator and other components.

.jpg)