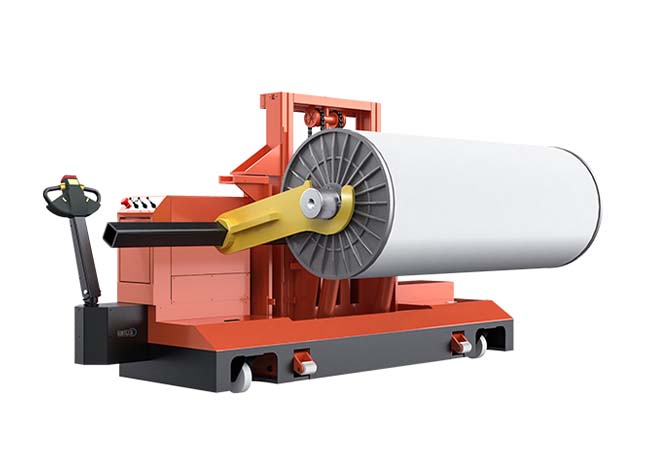

Material handling equipment is an essential tool in many production companies, such as textile machinery and industrial production because of the large volume and heavy weight of the materials or device. For example, warp beams and weaver’s beams in textile industry are important devices of weaving machine. However, it needs several people to lift one beam at the same time because of the heavy weight and large size of the beam, thus the motorized beam trolley, which is a kind of material handling equipment, occurring an important role in the beam-lifting process.

In spite of the material handling equipment saves the labor cost and protects the operation safety during the material handling process, there are some safety procedures for using material handling equipment need to be mentioned.

1. A detailed survey of the passing route and loading and unloading conditions at both ends should be done before transporting working of large equipment begins, which aids to understand the situation of the transport route then draw up a transport plan and make some necessarily handling measures.

2. When it is outdoor transporting, the investigation of roadbed sinking, road surface soft and permafrost opening and other conditions should be taken before handle with materials, and corresponding measures should be made, for preventing from tilting and overturning in the handling process, in addition, bridges, culvert, ditch along the passing route should be inspected, calculated even reinforced if necessary.

3. The road slope for some huge equipment transporting is not allowed to be greater than 15°, and obtain the consent of the manufacturer and take reliable security measures if cannot reach the requirements.

4. If there is a power transmission line above the transporting road, a safe distance should be maintained when passing through, otherwise isolation measures must be taken.

5. When using a trailer to transport large equipment, stability calculations should be made and measures for protecting from severe shock or vibration should be taken. Before starting, the horn should be sounded. The speed of the truck shall not exceed 5km/h-10km/h and it should be equipped with an leading truck and an escort liaison when transporting.

6. When unloading large equipment from the truck, the platform should be solid and should have sufficient width and length. The platform shall not have uneven sinking after loading.

7. When setting up the unloading platform, the height difference caused by the spring popping up and the hull floating up when the car is unloaded should be taken into account.

8. When unloading by using of 2 traction machine in different speed, it should take measures to make the equipment evenly stressed and have consistent traction speed. Towing point of force should be positioned below the center of gravity of the equipment.

9. The center of gravity of the towed equipment should be placed in the center of the towing plate. When hauling round equipment, the pillow wedge should be well padded while for some tall equipment with small bottom area, measures should be taken to prevent tipping; for thin-walled or easily deformed equipment, reinforcement measures should be taken.

10. The ground anchor of the hauling skid set should be calculated and should be checked frequently during working process. It is strictly forbidden to tie the hauling skid set on the unstable building or running equipment. It should have a survey of the underground facilities and calculate its bearing capacity when pile tying and hauling skid steer sets

11. It is strictly prohibited to pass or stay in danger zone that the towing wire rope guide pulley inside.

12. Measures should be taken to prevent equipment from rolling if needs to stop during transporting. There should be a red light to show the alarm at night.