Fabric relaxing machines are essential tools in the textile manufacturing industry, designed to reduce stress and deformation in fabrics. This results in improved quality and visual appeal of the final product. These machines are versatile and can be used with various fabric materials, including silk, linen, cotton, polyester, and nylon, both in pre-processing and post-processing stages.

How Fabric Relaxing Machines Work

Fabric relaxing machines operate by positioning the fabric within a spacious frame where it can relax freely. Diverse transmission mechanisms are used to allow the fabric to unwind and settle, reducing internal stresses and deformation. The machines offer adjustable settings for relaxation levels and duration, tailored to the specific type of fabric and processing requirements. This adaptability ensures optimal results, enhancing the fabric’s quality and comfort while minimizing production losses and waste.

Types of Fabric Relaxing Machines

Steam-Based Relaxing Machines:

These machines use steam to relax the fabric. The fabric passes through a chamber filled with steam, which softens and relaxes the fibers.

After steaming, the fabric is guided through the machine by rollers, ensuring even distribution of moisture and heat.

Adjustable tension settings allow for precise control over the relaxation process.

Heat and Mechanical Action Relaxing Machines:

This type employs a combination of heat and mechanical action. The fabric is fed through rollers that apply heat and pressure, causing the fibers to relax.

Some machines also incorporate moisture application systems to introduce water or steam during the rolling process.

These machines aim to alleviate tension and prevent puckering or distortion during manufacturing.

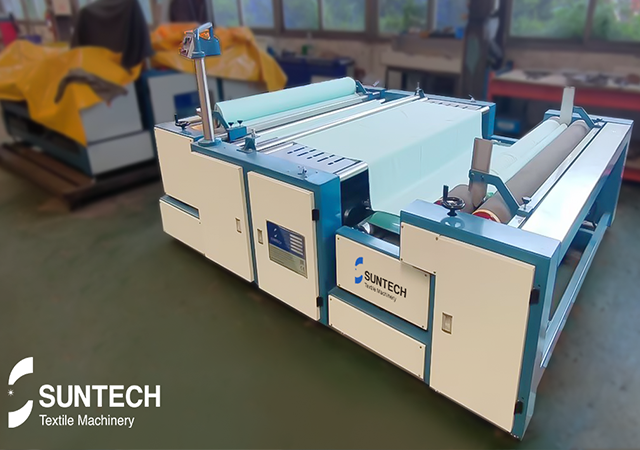

Enhanced Fabric Relaxing Machine: SUNTECH ST-FRM-VI(P)

The ST-FRM-VI(P) by SUNTECH is a state-of-the-art fabric relaxing machine designed to optimize fabric processing:

Independent Motors and Inverters: The machine unwinds fabric from two separate rollers driven by independent motors and inverters, ensuring tension-free feeding.

Air-Flotation Zone: This feature effectively relaxes the fabric, reducing processing time.

Automatic Edge-Alignment System: Ensures errors in edge alignment are limited to just 6mm, maintaining precise alignment.

Accurate Length and Width Measurement: Offers accurate length counting with errors no more than 0.1m/km and optional online width measuring devices.

Automatic Weight Device: Measures fabric weight with high precision, handling up to 1000-2000kgs.

Vibrating Table and Airflow System: When the fabric reaches the air duct on the conveyor belt, the vibrating table and airflow gently shake the fabric, releasing any remaining tension. This ensures that the fabric is entirely free from tension, preventing shrinkage during subsequent processing.

Commitment to Quality and Innovation

SUNTECH Textile Machinery has a long-standing reputation for developing, manufacturing, and globally distributing high-quality textile machinery. With products like the ST-FRM-VI(P) and the flagship ST-BS Beam Stacker, SUNTECH continues to lead the industry in reliability and productivity, driven by continuous innovation and enhancement of their product offerings.