With the development of clinical medical science, the packaging materials that used in the disinfection supply center are also updated from traditional cotton material to the fabric materials that made by advanced non woven fabric slitting machine, which includes medical non woven fabrics, crepe paper, rigid containers, etc. The supply of sterilized items has traditionally been packaged with double-layer cotton cloth with the longest 7-day validity period of use time. Although the sterilization effect is good, there are still many problems. Easily polluted by fibers and cotton wool and short storage time. The storage time of sterile items is affected by the dryness of the items after sterilization, packaging conditions and packaging materials. While compared with traditional cotton packaging materials, non woven fabric has ideal sterilization and antibacterial effects as packing materials, with lower packaging costs, which saves manpower and material resources greatly. So as to completely replace the pure cotton packing material in reusable medical equipment packing materials applications field, which is worthy of promotion and propaganda.

Characteristics of Medical Non Woven Fabrics

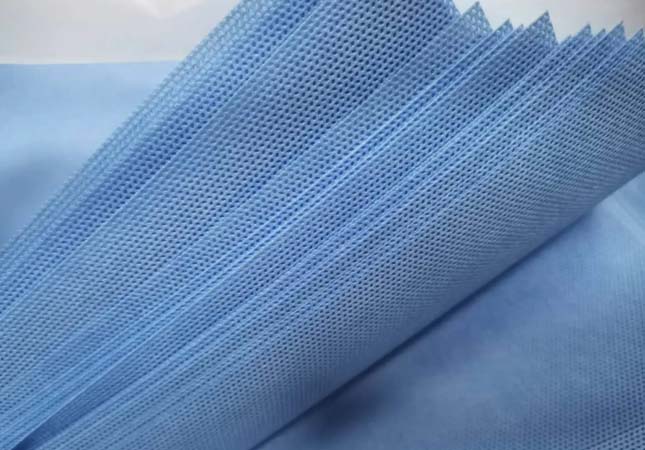

Medical non woven packing materials are suitable for high pressure steam sterilization, ethylene oxide sterilization and hydrogen peroxide low temperature plasma sterilization. They actually are fiber meshes in which textile fibers and non woven fibers are connected, so called non woven fabrics. Medical non woven fabrics are made of polypropylene and formed through a spunbond meltblown spunbond (SMS) composite process, of which spunbond layer can form a good mesh for achieving good barrier effect. The fiber diameter of the meltblown layer is only 2-4 μm, which forms a high-efficiency microbial barrier filtration.

1. High Penetration

Medical non woven fabric can form a unique barrier with its special porous arrangement, which can bend the steam and other media to penetrate towards inside to achieve a complete sterilization effect.

2. Nice Antibacterial Effect

Medical non woven fabrics have a low penetration rate for effectively blocking the dust particles, alcohol, plasma and other liquids, as well as bacteria and viruses. According to the data from bacterial permeation filtration test, the barrier effect against bacteria of medical non woven material is as high as 98% while the bacterial penetration transition rate of cotton fabric is only ranged from 8% to 30%. And the fiber structure of cotton fabric is deformed after repeated cleaning, resulting in sparse cloth holes or small holes that are not easily detected by the naked eyes, which is failed to isolate bacteria, also means that the antibacterial effect of medical non woven fabric is obviously better than that of cotton cloth.

3. Long Sterile Expiration Date

The expiration date of sterilized items is affected by various factors such as the fabric type, quality, tightness of sealing, sterilization quality, storage conditions, transportation methods and the number of hand touches of packaging materials in daily medical care work. It can be indicated from many repeated tests that the cotton fabric has limited expiration date as medical packing material for achieving antibacterial and even will be shorter as 10 to 14 days in wet and rainy seasons when temperature is under 25°C. However, all kinds of instrument bags and dressing bags that use medical non woven fabrics as packaging materials can last for 6 months are at the sterile storage room aseptically after sterilized by high pressure steam. But taking into account the storage conditions of sterile items in clinical departments, usually the valid time of the hospital items that used non woven as packaging material is 3 months.

Changing the medical packaging material from traditional cotton fabrics to non woven fabrics, which has higher sterilization and nicer antibacterial effects reduced the waste caused by frequent disinfection and sterilization and reduced the equipment damage, also saved human resources and medical costs. Non woven packaging materials not only is reliable and economical, but also help to establish a safe and modern image of the hospital and to improve the modern management level of medical equipment.