The Coimbatore-based Indian Texpreneurs Federation (ITF), representing 500 manufacturing units across Tamil Nadu, envisions significant growth for India's textile and apparel sectors through strategic initiatives. Improving cotton yield is a critical focus, with the potential to be a game changer for the entire value chain. Currently, India's cotton yield stands at 450-500 kg per hectare, which is significantly lower than leading producers like the US, China, Australia, and West Africa. The federation's convenor, D Prabhu, emphasized that increasing this yield to 1,000 kg per hectare could also substantially boost farmer income.

With appropriate policy changes and strategic direction, India has the opportunity to leverage the China Plus One strategy in apparel exports, aiming to enhance the current monthly export rate of $1.5 billion. In comparison, China’s monthly apparel exports are at $12 billion.

To expand its market share from the current 2% in the $35-billion US man-made fiber (MMF) apparel market, India needs to form knowledge partnerships with countries specializing in MMF and conduct similar initiatives within Indian clusters. Market diversification efforts should also target non-traditional markets like Japan, which has a $23-billion potential. ITF proposed selecting five exporting companies from five major clusters to work as a team, fostering a positive mindset and experience towards these new markets.

The federation also discussed innovative strategies such as satellite mapping of cotton cultivation to scientifically estimate crop size, thereby reducing speculation and helping farmers and the industry make informed decisions. Plans to boost e-commerce fashion exports were also highlighted, viewing it as an opportunity for SMEs to reach a global audience with lower costs and better margins. ITF suggested that both Central and State textile ministries establish a dedicated cell to support SME apparel and home textile makers in structuring their business for the fashion e-commerce market.

Addressing structural issues, such as the inverted duty structure on MMF, was another key topic. Currently, the duty structure is 18% for fiber, 12% on yarn, and 5% on fabric. Rationalizing this structure could bring more efficiency to the MMF manufacturing ecosystem, further supporting the sector's growth.

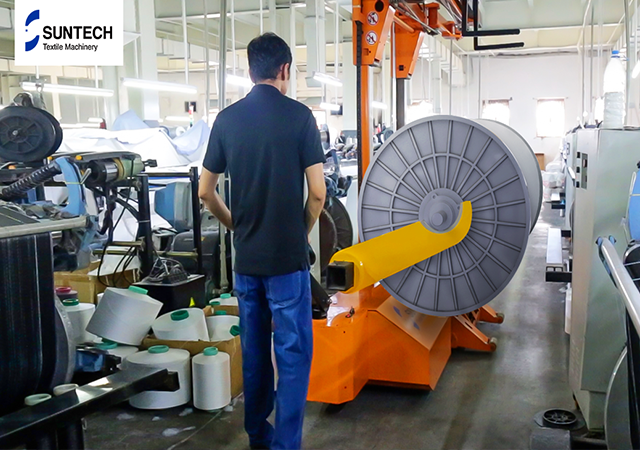

SUNTECH electric warp beam carrier are all designed technically. All our products in this production line are fully motorized and are all suitable for top/bottom beam transporting & weighting warp beams & inserting in weaving machines. All of them are equipped with motor, which achieves the lifting movement by the motor-driven with automatic quick lift. And we provides a required beam width. SUNTECH is a world-wide company that focus the research direction in fabric make-up machine, material handling equipment production, has the experience for more than 50 years, SUNTECH electric warp beam carriers all featured with high efficiency,low labor cost,convenient operation, guaranteed quality and safety. If you want to have more details of SUNTECH, the first step is calling us !