Beginning in the 15th century, France introduced wire heald jacquard loom machine from Italy, which came from China and was improved in Persia. It followed the linear pattern of the Chinese Dahualou jacquard loom machine. According to the difference of the drawing device, it is mainly divided into 2 categories: "Skittle" loom and "Smiple" loom.

The pattern control of both is on the jacquard loom machine side, while the "Skittle" loom has a small column hammer tied to the end of the pattern, dragger can pull down to lift the corresponding warp thread, while the "Smiple" loom will control the end of the pattern, which is fixed on the ground on one side of the jacquard loom machine, so operators can pull to the side of the jacquard loom machine to finally lift the warp.

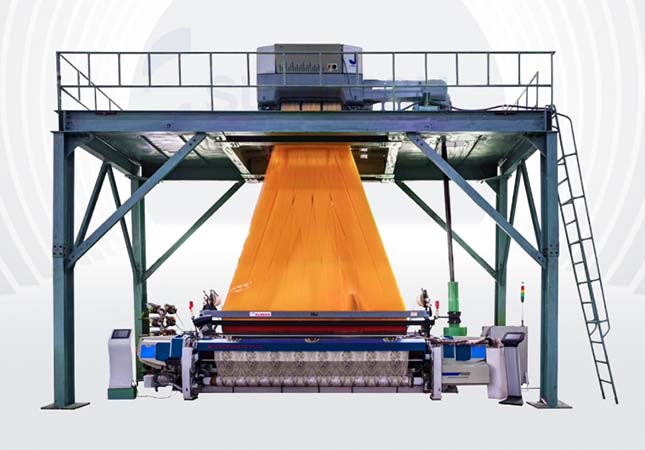

ST-JL SUNTECH JACQUARD LOOM MACHINE

At the beginning of the 17th century, Claude Dangon improved the jacquard loom machine based on the "Smiple" loom by changing the position of the dragger from vertical to horizontal, making it similar to the Chinese Yunjin Dahualou Loom. It breaks the limit of the number of the original thread that pulls the pattern in the vertical direction and greatly increases the cycle number of the flower pattern for weaving fabrics with larger jacquard patterns.

This type of loom is known as wide wire heald loom and was widely used till the mid-19th century. Among the patterns of the popular fabrics in the 17th - 18th centuries, there are many fabrics with large jacquard weaving technologies. The Baroque style fabric is a typical large jacquard fabric style, with a flower length of about 1 m, is majestic, and is mostly used for wall decoration. For example, the flower length of red Baroque fabric can reach 1.5 m.

In 1776, Philippe de Lasalle invented the coordinate method, which is the modern artisan design method. The initial design is a 10×10 grid, establishing a convenient bridge between the pattern design and the flower board, greatly improving the efficiency of flower board production, and providing a technological basis for the complexity and rapid change of the jacquard pattern design.

In the 18th century, there were 3 engineers, namely Basil Bouchon, Jean-Philippe Falcon, and Jacques de Vaucanson, who worked for improving the control parts of the jacquard loom machine and got significant improvements.

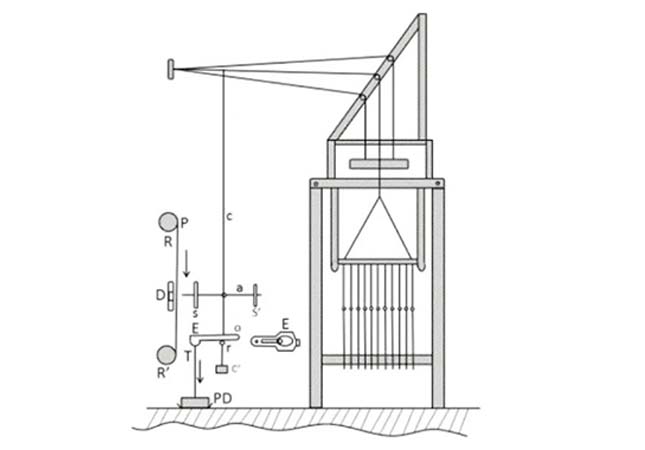

In 1725, Basil Bousson first invented a device for automatically screening jacquard warps, that is, pattern boards. The whole device is installed on the side of the jacquard loom machine and consists of a circle of continuous paper with holes, 2 upper and lower rollers for winding the paper, and a device with steel needles that can be pressed against the paper.

When the weft thread is woven in, the device D will press the paper sheet against the steel needle (a), and when there is a hole in the paper sheet, the steel needle will pass through the hole without moving, and the thread (c) connected to the steel needle to control the lifting of the warp thread will not move. When the worker steps on the device PD, E drives C to move downwards and lift the warp. On the contrary, when there is no hole in the paper, the steel needle and the lifting line (c) is pushed out and pushed out of E, when the PD is downward, (c) will not move downward, and the warp cannot be lifted, so that each warp can be moved according to The pattern design has been improved in different ways. The advancement of this technology is the beginning of pattern boards replacing linear pattern sheets. Although a worker is still required to control the pattern sheets, it reduces the probability of pattern errors. This is a very important reform and innovation of jacquard weaving technology.