As we all know, the textile industry is an important industry in China and even countries around the world, because textile products are widely involved in our daily lives. For example, the fabrics, fabrics, products, clothing, school bags, packaging, etc. we use are inseparable from textiles. This is destined to become more It has become more and more developed.

Although the textile industry is mainly labor-intensive and the technology is relatively backward, it is a pillar industry in many countries because of its huge system, which solves a large number of labor problems. However, due to the huge volume of textiles, the textile industry is bound to face many warehousing and management problems. How can the warp beams scattered on the ground be stacked to save space? How to manage to efficiently store?

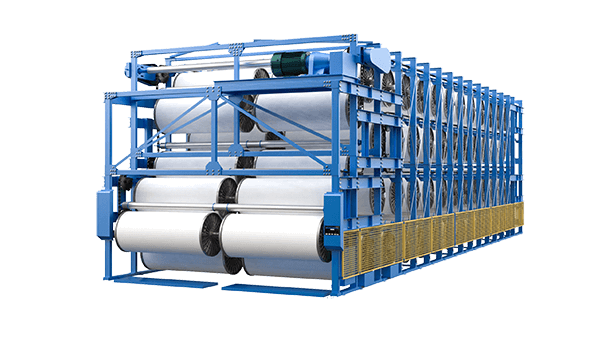

With the development of artificial intelligence, digital applications have gradually entered the textile industry to optimize the structure of the textile industry. Suntech, an established textile machinery company, integrates digitalization, informationization, and intelligence into textile machinery manufacturing, and uses 50 years of design experience and technology to precipitate the intelligence of R&D and production. The beam stacker can just solve the storage problems of many factories.

What are the storage problems in the textile industry?

1. Warp beam is piled on the ground for a long time, it is easy to be damp and rust, shorten the service life;

2. Warp beams and warp beams are stacked in a mess, which not only takes up a lot of warehouse space, but also makes the whole warehouse look down several grades, which damages the overall image of the company;

3. Stacked on the floor irregularly, the carpet-style management cost is extremely high, time-consuming and labor-intensive;

4. Because there is no reasonable planning, the required Warp beam may be stacked inside, and the temporarily unnecessary Warp beam may be stacked on the outside, which will waste a lot of time and manpower and material resources during transportation, reducing work efficiency;

5. Due to the large number of Warp beams, the textile storage area is large, and the rent and storage management costs are too high.

6. Because the Warp beam is large, heavy, and easy to roll, it is easy to roll off during storage or handling, causing safety problems such as personal injury.

How does beam stacker solve the warehousing problem in the textile industry?

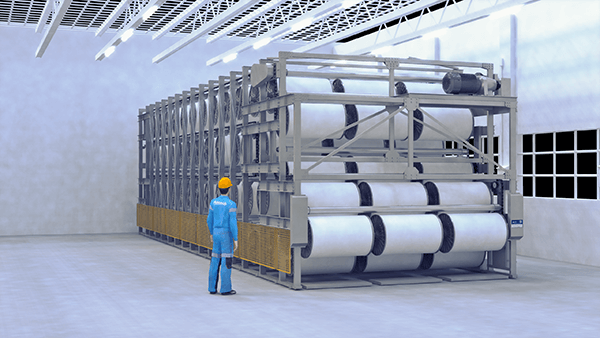

1. The beam stacker allows the Warp beam to be stacked in multiple layers to make full use of space, save a lot of space, and reduce storage costs.

2. The layer height of the beam stacker can be adjusted freely according to the requirements of the height of the Warp beam, the stacking appearance is beautiful, and the image, grade and pattern of the enterprise are improved.

3. The beam stacker can access the Warp beam intelligently, the computer calculates the optimal and shortest path, and quickly stores the Warp beam. It can also be quickly taken out when it needs to be taken out, which improves work efficiency.

4. The beam stacker can realize the classification management and storage of the Warp beam, which is convenient to quickly find and retrieve the required Warp beam.

5. The whole process of digital monitoring, just click and view on the smart screen, you can know the location and storage of the warp beams, reducing management costs.

6. The beam stacker uses a safety fence to ensure that the Warp beam will not roll off. Through digital monitoring, it is determined whether there are foreign objects in the beam stacker and whether it is stored in place to ensure storage security.

Advantages of Suntech beam stacker

1. The seven intelligent applications of beam stacker can realize fast access, intelligent adjustment and visual supervision of Warp beam, reducing management costs.

(1) Intelligent access axis, automatically select the shortest access axis path

(2) Intelligently search the position of the axis according to the axis number

(3) ERP system can be connected to realize data synchronization and sharing

(4) Scan code function can automatically enter information

(5) Customizable language

(6) Customizable software

(7) Remote control by mobile phone APP can be realized

2. The seven security guarantees of beam stacker ensure the safe storage and access of Warp beam.

(1) CE certificate, directive 2014/35/EU, in line with EU electrical safety and mechanical safety standards

(2) Chain synchronization detection technology to ensure zero accidents

(3) When a foreign object enters the beam stacker, the photoelectric will detect it and the machine will issue an alarm

(4) The limit switch ensures that the shaft will not hit the column

(5) Safety fences on both sides

(6) The design load-bearing capacity of the hanging shaft tube is 1.5 times the actual weight of the shaft, and the safety factor is high

(7) The safety hanging chain provides double guarantee for the hanging scroll

Suntech, the manufacturer of beam stacker, is a well-known and established technologically innovative textile machinery enterprise. It started with textile and storage machinery and involved various textile machinery and equipment in the storage, handling, inspection, and packaging of finished fabrics. Among them, beam stacker is a classic The product has won many awards, and applied for a number of patented technologies such as beam stacker system operating software and chain synchronization detection, which are favored by international textile companies.

Suntech smart beam stacker uses brand-selected materials and adopts advanced beam stacker design technology to ensure quality and stable equipment performance.

(1) Guarantee of incoming materials, purchase of raw materials for large steel mills in accordance with international standards

(2) Precision guarantee, precision parts: such as sprockets, chains, and rollers are all processed by high-precision CNC centers

(3) Processing guarantee, CNC cutting and welding are tested by flaw detection, test report can be provided

(4) Unique shot blasting process: improve the fatigue strength of the workpiece; increase coverage (good paint adsorption); good surface roughness, more beautiful

(5) Double-layer guaranteed painting process: epoxy primer + surface metal paint suitable for elevator process, highly anti-rust

(6) European standards: CE standard machine safety mode + the latest chain synchronization automatic detection technology, zero accident protection! All electrical appliances adopt the French Schneider brand

(7) SGS factory audit, ISO management standard

After 50 years of technical polishing and functional optimization, it currently has more than 4,500 customers and 15,000 machine installation cases around the world. With excellent quality assurance and considerate after-sales service (overseas technical support, 12-month warranty), it has won a lot of praise from customers , The return rate is very high. At present, beam stacker is in short supply. Customers who want to buy beam stacker, please inquire in time, and we will tailor it according to customer needs.