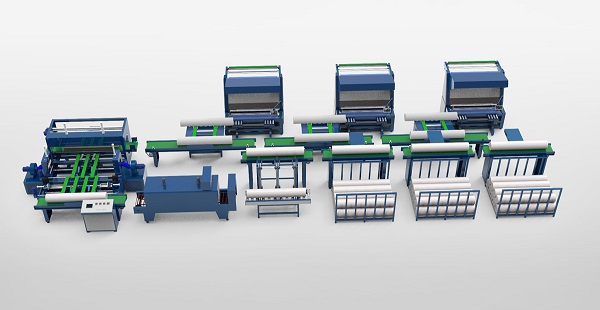

For factories, fabric inspection and packaging are inseparable in many cases. After the fabric has been inspected to determine that there are no defects, the next step to complete is the packaging fabric. At this time, the fabric inspection and packaging line is crucial, it can save time and improve the efficiency of the factory to a great extent. SUNTECH, one of the fabric inspection machine manufacturers, SUNTECH's AI intelligent fabric inspection and packaging line can achieve this effect.

AI intelligent fabric inspection and packaging line integrates a series of high-tech actions, including: high-speed camera fabric inspection → automatic cloth breaking → automatic girdle sealing → automatic labeling → automatic cloth roll film packaging → intelligent partition → full Automatic stacking.

Traditional textile fabric inspection generally adopts manual fabric inspection, but there are many problems in manual fabric inspection.

1. Slow speed, low output and poor efficiency. Generally, inspectors can only detect about 200 defects per hour. If this range is exceeded, missed inspections and misjudgments are prone to occur. However, functional and high-performance fiber fabrics are widely used in aerospace, aviation, military industry, navigation and other fields. The fabrics require zero defects and zero leakage, and manual inspection is difficult to meet high standards.

2. High requirements for inspectors. Manual fabric inspection has certain technical requirements and vision requirements for inspectors. Long-term concentration of vision can easily lead to eye fatigue, occupational diseases, and labor intensity is not low.

3. The error is high. Manual fabric inspection is limited by the inspector's subjective consciousness, personality, environment, cognition and other factors.

4. It consumes labor. Relevant information shows that: Generally, 500 traditional looms need to be equipped with 2.5 cloth inspectors, 2.8 cloth repairers, and corresponding sampling personnel and other auxiliary personnel, and the labor cost is relatively high.

5. The width is small. The traditional manual fabric inspection can only inspect the cloth with a smaller width, which is not suitable for the width requirements of modern looms. If the width is expanded, it is bound to reduce the speed and increase the inspection load.

Suntech intelligent fabric inspection and packaging line inspection machine overcomes the disadvantages of manual inspection, integrates inspection and packaging, and automatically completes inspection and packaging, which is more convenient and has the following advantages:

1. Fully automatic. Suntech fabric inspection machine can detect fabric defects online or offline, determine the location of the defect, classify and score according to the size, hazard, and impact degree of the defect, and issue an alarm for serious defects or implement measures such as shutdown or cutting.

2. Applicable to all kinds of fabrics. Suntech fabric inspection machine can detect the common basic structure and changing structure of fabrics, including cotton, linen, silk, wool, chemical fiber and blended yarn fabrics and other fabric raw materials.

3. High pass rate. The production output of Suntech fabric inspection system equipment is significantly higher than that of manual fabric inspection, even several times higher. The correct rate of automatic fabric inspection fabric defect detection is more than 95%, which is much higher than that of manual fabric inspection, missed inspection rate and false inspection rate. The judgment rate is less than 5%, which is much lower than manual fabric inspection.

4. Fast speed, adjustable speed. The production speed of Suntech's automatic fabric inspection can generally reach more than 120m/min, and the maximum can reach 300m/min. The inspection speed can be adjusted according to the needs. The actual inspection speed is related to the machine width and defects.

5. Automatic length count review. The Suntech fabric inspection machine is equipped with a length measuring device, and can also check the length of the sewing material. In traditional manual fabric inspection, it is necessary to visually check whether there are defects on the surface of the sewing material. If there are defects such as yarn defects, weaving defects, stains or chromatic aberration, it is necessary to immediately mark the edge of the sewing material for repair or removal. Suntech fabric inspection machine saves these troubles.

If you want to implement fabric inspection and packaging efficiently and quickly, take a look at SUNTECH’s fabric inspection! AI intelligent fabric inspection and packaging line is waiting for you. The fabric inspection machine price here is also very competitive. Don’t hesitate and come to take a look!