Understanding the transformative power of automation and artificial intelligence (AI) in the textile industry is crucial. This article explores how enterprises can strategically implement automation technologies and leverage AI advancements to enhance various aspects of their workflows and processes.

Adopting Automation Gradually:

Enterprises must carefully assess the applicability of automation technologies to different stages of their processes. Initiating the transformation with simpler tasks and gradually expanding to more complex processes ensures a smooth transition. This approach also allows for a thorough evaluation of cost-effectiveness before making significant investments in automation.

Professional Support for Successful Implementation:

Successful automation transformation requires professional technical support and maintenance. Reliable automation technology service providers offer essential consultations and support to guarantee the seamless execution of automation processes. Trained professionals play a key role in the management and maintenance of automation technology, emphasizing the importance of attracting and cultivating talent through training and recruitment.

Intelligent and Data-Driven Management:

Automation technology facilitates intelligent and data-driven management, leading to improved production efficiency and product quality. Implementing intelligent systems for real-time monitoring and optimization of production processes enhances efficiency and ensures high-quality outcomes.

Methods of Transformation in the Textile Industry:

Artificial Intelligence in Intelligent Manufacturing:

Advancements in AI bring forth intelligent manufacturing for the textile industry. This includes feature extraction, optimization, planning, and scheduling in the production process. The focus should now shift towards enhancing intelligence levels through knowledge acquisition, knowledge base construction, deep learning, and optimization decision-making functions for true intelligent manufacturing.

AI in Textile Fabric Design and Analysis:

AI technology has revolutionized textile fabric design, defect identification, fabric performance evaluation, cotton classification, and grading. Machine vision and machine learning technologies assist in detecting and analyzing defects, color differences, and patterns, significantly improving the identification and analysis capabilities of the industry.

Trend Research with AI:

AI has immense potential in analyzing textile and fashion trends through data accumulation and processing. Computer vision and image processing quickly retrieve user preferences, enabling accurate trend predictions. AI's superiority over current modeling methods makes it an ideal tool for the next stage of textile and fashion innovation, providing insights into consumer preferences and consumption habits.

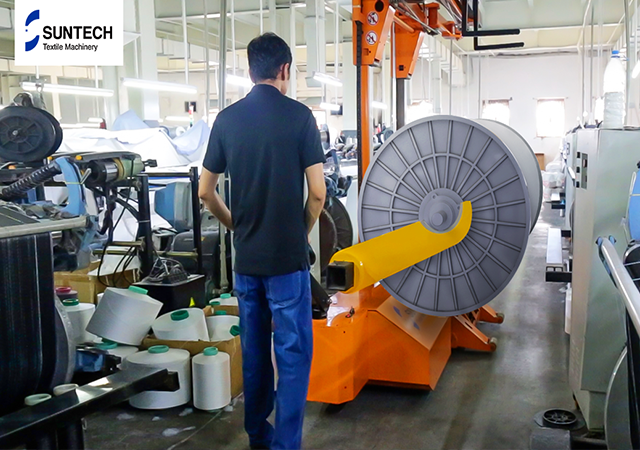

SUNTECH Textile Machinery has revolutionized the production landscape by introducing the motorized beam trolley with precise mechanical design. The mechanical parts unload the warp beams and cloth rolls from the loom and transport them seamlessly to the beam storage area, where they are lifted and stored using advanced technology. The trolley is highly responsive, stable, adaptable to different environments, and capable of carrying heavy loads in fewer trips. It addresses the drawbacks of manual handling, reduces the labor burden on textile workers, enhances work efficiency, lowers labor costs, and improves production efficiency and product quality. With 50 years of design experience and technological advancements.

SUNTECH Textile Machinery is committed to continuously innovate and upgrade its products to cater to the changing needs of the textile industry.

The integration of automation and AI technologies is reshaping the textile industry. Enterprises can strategically implement these advancements to streamline processes, enhance efficiency, and stay ahead in a rapidly evolving market. The journey towards intelligent manufacturing and data-driven decision-making represents a significant leap towards sustainable development in the textile sector.