Beam storage system is an important equipment of any textile industry that needs beam staker to handle various heavy beams. They allow you to stack multiple beams together to form beam stacker system and increase your production efficiency. Also enable you to move or stack the heavy beam in a rather safer operation. A perfect beam stacker means a lot to the textile factories, especially for some textile manufacturers that in medium and large scale, for they need countless of beams in different fabric production lines.

There are a few things to consider when choosing a beam storage system, such as the number of beams you want to stack, the weight and size of your beams and how you need to stacking the beams. Some beam storage systems are very large and require a lot of space, while some of them are much smaller and can be operated in a narrow space. Thus, when selecting a beam storage system for your beam storage system, it is essential to consider the type of beams being stored, as well as the environment in which the storage system will be used.

Factors to Consider of Choosing Beam Storage System

1. The weight and size of your beams

You will need to calculate the total weight of all the beams before selecting a beam storage system. And mark some special beams if their size or shape is differ from general beams.

2. Your Budget of The Beam Storage system

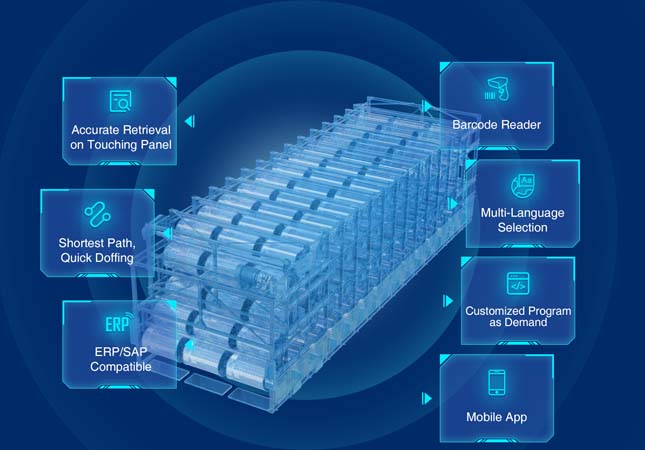

There are different type beam storage system, the most advanced type is the computerized beam storage system, which also has a relative higher price that even make them out of reach for many textile factories. So before choosing a proper beam storage system for your warehouse, you must be clearly about how much economic pressure you can afford.

3. The Quality & Safety Guarantee of The Beam storage system

Generally, a beam storage system is made of steel and commonly is big and heavy for stacking countless of beams and operating like a beam caousel to transport exact beam when you need to use it. So one of shortcomings of a beam storage system is it may cause safety problems if don’t be handled properly. Usually you need check if the beam storage system has the basic security design such as chain synchronization automatic detection technology when choosing a beam storage system.

4. Acceptable Size of The Beam storage system

Beam storage system greater the space utilization, compare with the original method of stocking beams, beam storage system saves as much space as it can by utilizing the higher space. However, as a beam storage system, it is impossible to be as small as the weaving machine , it must need a proper space to be settle down. So before determining the beam storage system, firstly you need to measure the width and length of your warehouse, then calculate the number of beams you have. Most beam storage system suppliers will provide you with several options of beam storage systems, which are from smallest size to largest size, you can choose the most proper beam storage system according to your needs.

With the development of textile industry, the weaving efficiency is increased by the applications of many advanced textile machines, the huge demands for clothing and fabrics force the garment factories and large scaled textile manufacturing enterprises to produce as many kinds of cloth in as short time as they can. Therefore, the invention of beam storage system, especially the appearance of some advanced computerized beam storage systems saves the time cost in searching certain beam, and increases the space utilization of textile industry.

We suggest you consider and choose the most suitable beam storage system to meeting all your needs through the above aspects, or add your own customization to the beam storage system manufacturers, it is acceptable for some advanced textile machinery and material handling equipment manufacturing enterprises.