The textile industry of the biggest industries in the world, which is worth more than three trillion US dollars across various stages of production. However, it is also one of the highest polluting industries with a massive amount of waste. Not only does it affect the environment, but it also impacts the development of factories. A large number of sources of defects produced through the textile production process, among them, more than 80% of defects occur during the process of knitting.

Normally, knitted fabrics are produced by a circular knitting machine. It will not stop when defects appear until someone intervenes. And lots of defects are smaller than one millimeter and they are almost invisible to human eyes, thus, a particular problem occurs. The continual defects will proceed onto the next stage of production.

Then, the fabrics are dyed as well as finished with relatively expensive processes. Therefore, the defects are often missed again and sent onto final garments. Defects at this stage are much more visible and will be identified as an issue. Finally, the problem garments are thrown out due to these knitting defects, which waste a lot of money.

The faults can only be perceived after quality control in following stages when they are more visible. After accumulating and propagating, the defects become more expensive, which will increase waste and financial losses.

SUNTECH is one of the best fabric inspection machine manufacturers, our automatic fabric inspection and packing line can help to solve this problem. It can identify production defects at its earliest stage with camera inspection, which can detect all defects and irregularities. At the time it detects defects, it will alert workers immediately and prevent further faults.

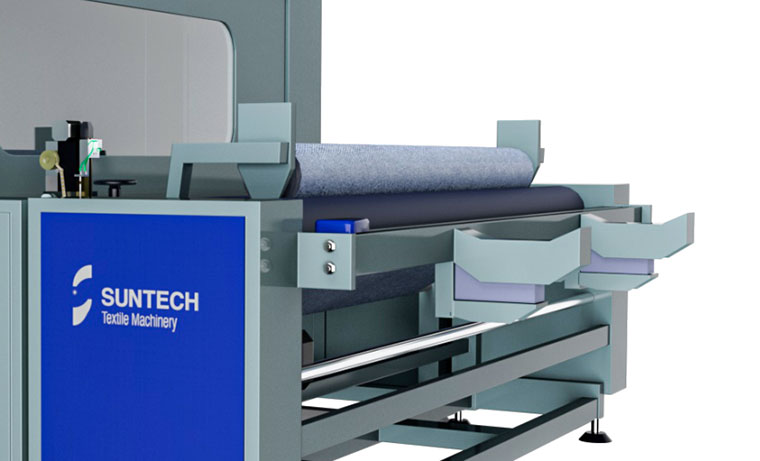

Automatic Fabric Inspection And Packing Line

SUNTECH automatic fabric inspection and packing line is one of the most popular lines in the worldwide market, which is combined with the state of art technology and designed to be operated automatically.

Features

AI Technology

SUNTECH fabric inspection and packing line is used with the state of art technology, which includes camera inspection, automatic cutting, taping, labeling, packing, sorting and intelligent stacking.

High Efficiency

Set packing system supports Max. 10 sets fabric inspection machines for online packing. And packing speed up to 7 rolls/min.

Intelligent Management

Automatic liner cutting, taping, labeling, vacuum packing and stacking. So only one operator is enough, which extremely reduces labor costs and improves production capacity. Fabric rolls can be sorted after packing with a smart classification function, which makes overall management and ontrol easier.

Customized solutions

SUNTECH automatic fabric inspection and packing line provides customized solutions with different packing effects, including vacuum packing and normal packing line with hot air blowing and punching device. Furthermore, it also provides solutions according to limited space.

SUNTECH is a professional worldwide enterprise with decades of experience and research. We are committed to providing customers with excellent products and customized service. Our experienced experts will offer customers timely and effective integrated services in pre-sales consultation, sales, maintenance, and comprehensive after-sales support, giving customers the ultimate and comprehensive service experience.

Welcome to visit our website for more information. We are always ready to give you the best service.