Meltblown nonwoven fabrics have the following characteristics:

1. The fiber web of meltblown nonwoven fabric is composed of fine shorter fibers;

2. The uniformity of the fiber web of the meltblown nonwoven fabric is very good, and the hand feel is particularly soft;

3. The filtration performance and liquid absorption of this meltblown nonwoven fabric are relatively good.

Meltblown nonwoven fabric is a kind of nonwoven products, which is produced by non woven machine. Most of its raw materials are polypropylene (pp material) pellets. The process of meltblown nonwoven fabric is polymer feeding, melt extrusion, fiber Forming, fiber cooling, web formation, and finally consolidation into cloth. It is called cloth because of its appearance and certain properties.

Meltblown nonwoven products are generally used in filter materials, medical and sanitary materials, clothing materials, battery diaphragm materials, wiping materials, etc. In addition, meltblown nonwoven fabrics are mainly used in spray paint and chemical industries. The masks made of meltblown nonwoven fabrics are mainly used to filter micron-sized particles such as dust, microorganisms, and haze, which can be called the "heart" of masks.

General medical masks are mainly composed of three layers. The inner and outer layers are spunbond nonwoven fabrics (S), and the middle filter layer is meltblown nonwoven fabrics (M). The microfiber structure and static electricity are used to adsorb virus dust and droplets, and play a barrier and protection role.

The production chain of masks is roughly: polypropylene-meltblown material-meltblown cloth-mask. The upstream chemical raw materials polypropylene and meltblown materials have excess domestic production capacity, and the prices remain stable. Chin’s meltblown nonwoven fabric industry has always been relatively small. About 10,000 tons of meltblown nonwoven fabrics are used for mask production each year, and the daily output of large enterprises is about 10 tons. Under normal circumstances, the market demand is relatively stable, and the industry as a whole presents the characteristics of small and scattered.

Due to the impact of the COVID-19, the use of masks has surged, and it is difficult for any country to meet such a large demand for masks in a short period of time. A large number of masks are online, but there is no meltblown nonwoven fabric, which has become a bigger bottleneck for the expansion of masks. Even if the price has soared from 20,000 yuan per ton before the epidemic to 400,000 yuan, it is still "hard to find a piece of cloth".

Equipment is an important reason why it is difficult to increase the output of meltblown nonwoven fabric in a short time. Some core equipment such as meltblown die heads and meltblown templates need to be imported, and the supply cycle and assembly time are relatively long. It takes 3 to 5 months at the fastest, half a year or even a year to produce the product. At the same time, the meltblown production process is relatively high, and some professional technologies need to train talents.

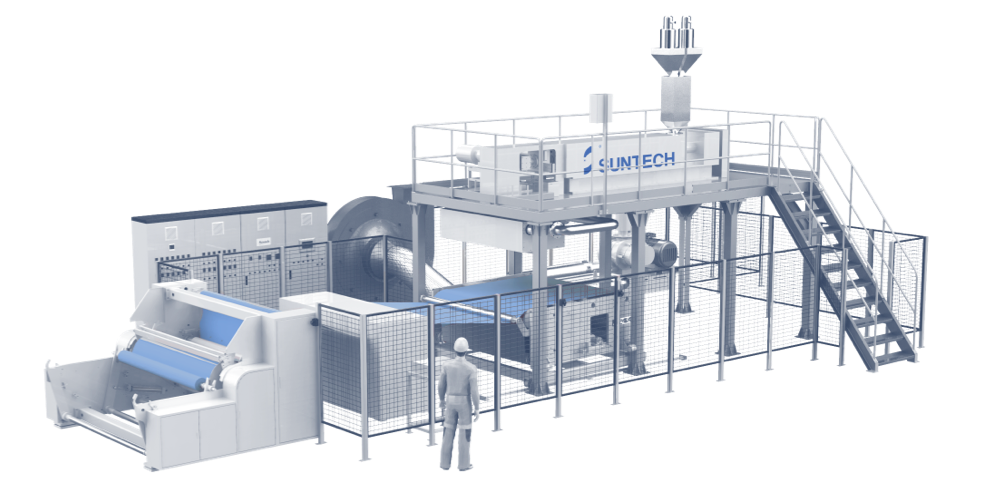

SUNTECH, a professional nonwoven fabric machines manufacturer, provides high quality meltblown nonwoven machines with competitive prices.

The width of the disposable flat mask is 17.5cm and the length is 19.5cm, and a 25g meltblown nonwoven fabric is generally used. One ton of meltblown nonwove fabric can make about 1.1 million finished masks. The N95 mask with four layers of fabric uses 25g/per square meter of meltblown nonwoven fabric, which can produce 400,000 pieces in a rough situation. Fish-type KF94 meltblown nonwoven fabric uses 25g/square meter, which can produce about 300,000 pieces.

Gram weight×film width×perimeter of main shaft/1000000/quantity of meltblown nonwoven fabric for each mask, the formula is 25*260*219.8/1000000/2 = equal to the number of sheets, the above data are all without waste In this case, it is estimated that some wastes need to be removed. The data can only be used as a reference, and the actual situation shall prevail.