According to the latest customs statistics, the export value of Chinese textile and apparel products soared to $291.22 billion in 2020, marking a year-on-year increase of 9.6%. Textile exports alone reached $153.84 billion, a substantial 29.2% increase from the previous year, accounting for 58.2% of the total industry export value.

Despite such robust growth, the subsequent years saw a slowdown, influenced by both complex domestic and international situations. In 2022, China’s clothing exports edged up to $175.4 billion, a modest increase of 3.2% year-on-year, showcasing a deceleration in growth. This highlights a crucial point in the textile production chain — the need for efficiency in the final stages of textile processing, which includes inspection and packaging.

Key Stages in Textile Production

The textile production process is extensive, starting from warping, beaming, sizing, and drawing-in, to weaving and the critical stage of finishing. Of these, finishing is often the most time-consuming and labor-intensive, especially during the fabric inspection and packaging phases. These stages are where inefficiencies can bottleneck the entire production line.

Enhancing Fabric Inspection with Technology

Fabric inspection is vital in ensuring the quality of textiles, as defects can significantly impact the final garment quality. Traditional inspection methods are manual and prone to human error, making the adoption of automated technologies like dedicated fabric inspection machines a game-changer. These machines streamline the detection of defects such as weaving errors, dye inconsistencies, and print issues.

The "4-Point Inspection System" is widely employed in this process, where fabric defects are scored within a meter of textile, ensuring high standards of quality control before the fabric moves to cutting and garment construction.

The Strategic Role of Automatic Packaging Machines

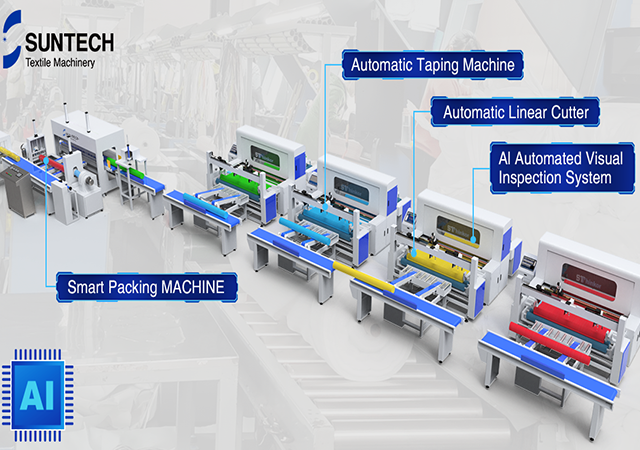

After inspection, proper handling and packaging of fabric rolls are paramount. The textile industry requires systematic packaging not only to maintain the quality and organization of fabrics but also to facilitate easy transportation to garment manufacturing sites. Automatic packaging machines, such as those offered by SUNTECH Textile Machinery, play a crucial role here.

These machines optimize the packaging process, enabling an operator to manage high volumes efficiently. With intelligent features and smart classification systems, automatic packaging machines ensure textiles are ready for the next phase of production without delay or damage, significantly boosting overall productivity.

Conclusion

As the textile industry continues to evolve in the face of fluctuating demand and economic challenges, integrating advanced technologies in fabric inspection and packaging is essential. Automatic packaging machines not only streamline operations but also enhance the efficiency of the textile production chain, ensuring that industries can keep up with market demands while maintaining high standards of quality. This strategic integration not only saves time but also substantially cuts costs, heralding a new era of efficiency in textile manufacturing.