In the field of textile production, as production demand continues to increase, how to efficiently use limited space has become an important issue facing many companies. Although traditional fabric relaxing methods can relieve tension, they require a large area of space for operation and storage. The birth of the fabric relaxing machine has completely changed this situation. With a more compact design and efficient process, it has become the best solution for saving space in modern factories.

Limitations of Traditional Fabric Relaxing Methods

Large Floor Space

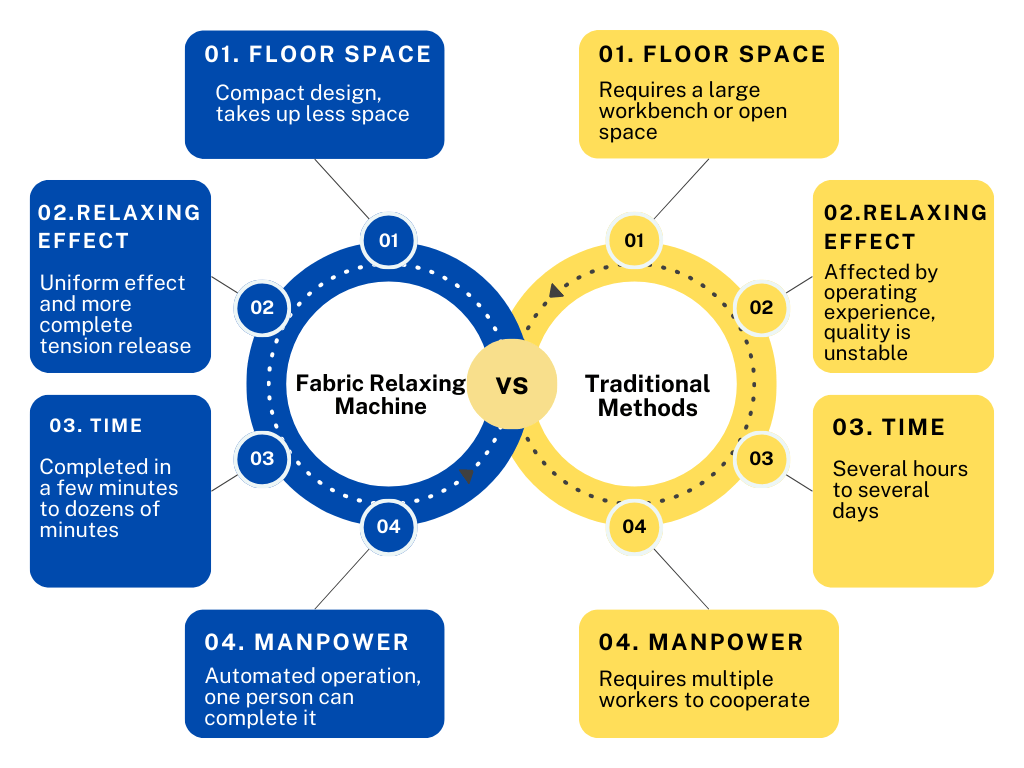

Traditional fabric relaxing methods usually require the fabric to be laid flat on a large workbench or cloth laying rack, which not only takes up a lot of space but also limits the overall layout optimization of the factory.

Time-Consuming and Labor-Intensive

Manual relaxing requires multiple workers to work together, which consumes manpower and time. Moreover, the manual method is easily affected by human factors, and the relaxing effect is uneven.

Difficult to Adapt to Large-Scale Production

With the increase in order volume, the efficiency of traditional methods makes it difficult to meet the needs of modern textile factories for rapid delivery, and low space utilization has become an important factor restricting the increase in production capacity.

Space-Saving Advantages of Fabric Relaxing Machines

Compact Design

The fabric relaxing machine adopts a vertical or modular structure design, which greatly reduces the footprint. Compared with the traditional flat laying method, it can compress the operating space originally required to half or even less.

Integrated Process Flow

By integrating the relaxing, and shaping steps into one device, the fabric relaxing machine avoids the additional space requirements caused by the separation of multiple processes. The full process operation completed inside the equipment reduces the dependence on external space.

Efficient Storage Solution

Some advanced fabric relaxing machines also combine intelligent storage functions, and the relaxed fabric can be directly wound and stored, avoiding the additional sorting and storage space requirements in traditional methods.

Improve Production Efficiency

Automated Operation

Modern fabric relaxing machines are equipped with intelligent control panels, so that one operator can monitor the entire machine operation, greatly reducing the involvement of workers.

Shorten Relaxing Time

Traditional methods may take hours or even longer to relax fabrics, while the efficient process of fabric relaxing machines can shorten the time to a few minutes to tens of minutes.

Improve Relaxing Uniformity

Through the precisely controlled triple process, the fabric relaxing machine can ensure that each piece of fabric reaches the ideal relaxing state, avoiding the unevenness caused by manual operation.

Advantages of Fabric Relaxing Machines

Optimize Space Layout

Reducing reliance on spreading racks and large workbenches allows factories to more flexibly adjust production line layouts, leaving more space for other equipment and processes.

Reduce Operating Costs

By saving space, shortening time, and reducing manpower, fabric relaxing machines help companies significantly reduce operating costs. Especially in areas with expensive land rents, the value of space savings is particularly prominent.

Improve Production Flexibility

In traditional methods, space constraints can lead to production bottlenecks. The efficiency of fabric relaxing machines enables companies to respond to order needs more quickly and improve market competitiveness.

SUNTECH Case

After the Brazilian garment manufacturing company introduced the fabric relaxing machine, it eliminated the originally required spreading space and released more than 50% of the operating space. At the same time, production efficiency increased by 35%, saving labor costs.

Conclusion

The fabric relaxing machine has gradually become an important equipment in modern textile factories due to its space-saving and efficient operation. It not only solves the space and efficiency problems in traditional relaxing methods, but also provides more possibilities for the future development of enterprises. In today's pursuit of high efficiency and environmental protection, the application prospects of fabric relaxing machines are unlimited.