The textile industry, a cornerstone of global manufacturing, is experiencing a transformative wave with the integration of cutting-edge automation technology. This shift is revolutionizing various aspects of textile production, offering significant benefits for manufacturers and setting the stage for a more efficient, quality-focused, and sustainable future.

Key Benefits of Automating Textile Factories

1. Boosted Production Efficiency:

Automation technology enables textile factories to operate around the clock with minimal downtime, resulting in increased production rates and faster order fulfillment.

2. Consistent Product Quality:

Automated processes ensure uniform product quality, reducing defects and variations, and maintaining high manufacturing standards.

3. Reduced Labor Costs:

Automation decreases the reliance on manual labor, leading to lower labor costs and allowing human resources to focus on more complex and creative tasks.

4. Improved Workplace Safety:

Automated machinery can handle hazardous and physically demanding tasks, reducing the risk of workplace accidents and injuries.

5. Enhanced Speed and Accuracy:

Automated equipment performs tasks faster and with greater precision than human workers, improving overall production speed and reducing errors.

6. Long-term Cost Savings:

Despite the initial investment, automation technology leads to significant long-term savings through reduced labor costs, increased efficiency, and minimized material waste.

7. Energy Efficiency:

Modern automation technologies often feature energy-saving capabilities, optimizing resource consumption and promoting environmentally friendly production practices.

Revolutionizing Production with Intelligent Systems

Implementing intelligent packaging lines can significantly reduce reliance on manual labor, leading to cost savings and increased productivity. Automated systems provide greater precision and uniformity, improving product quality and reducing error rates. Advanced sensors and data analytics in these systems enable real-time monitoring and quality control, further refining the production process.

1. Reduced Lead Times:

Automation streamlines workflows, cutting lead times and enabling faster product delivery to customers.

2. Customization and Personalization:

Automation facilitates the quick adjustment of production parameters to cater to individual customer preferences, expediting the production of personalized textile goods.

3. Minimized Material Waste:

Automated processes precisely control measurements, reducing material waste and lowering costs while also benefiting the environment.

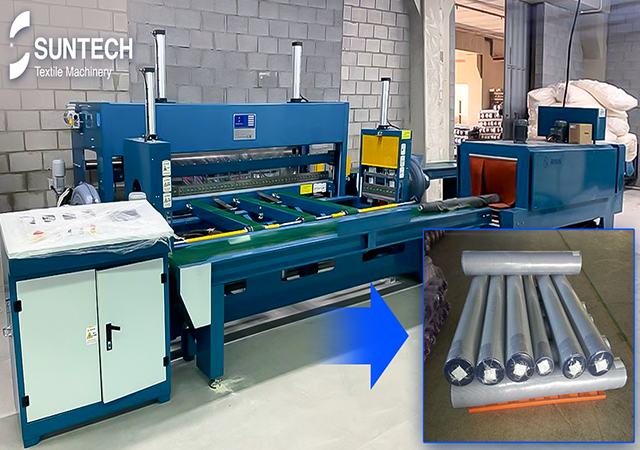

SUNTECH Automatic Packaging Machine

The SUNTECH Automatic Packaging Machine exemplifies the integration of automation in the textile industry. It seamlessly combines primary processes like filling, wrapping, and sealing with preparatory and follow-up tasks such as cleaning, stacking, measuring, and imprinting on packaging items. This machine also includes automatic inspection to quickly eliminate substandard packaging, significantly enhancing productivity, reducing labor intensity, meeting large-scale production demands, and maintaining cleanliness and hygiene standards.

Competitive Advantage:

Automation gives textile manufacturers a competitive edge by enabling faster, more efficient production of high-quality goods compared to competitors.

Adaptability to Industry Trends:

Automation helps manufacturers stay competitive by quickly adapting to new technologies, materials, and production methods in the ever-evolving textile industry.

A Bright Future Ahead

To meet the global demand for high-quality garments, textile manufacturers must evolve, and factory automation offers a promising path forward. By addressing monotonous, hazardous, or physically demanding tasks, automated machinery reduces the need for human intervention, resulting in significant cost savings, improved safety, increased efficiency, and reduced fabric wastage. Automation holds the potential to revolutionize textile production, enhancing efficiency, quality, and safety while reducing costs and minimizing environmental impact. As the textile industry continues its transformative journey, automation stands out as a beacon of progress, guiding the way to a brighter and more sustainable future.