Our country is the largest textile and apparel producer and exporter in the world, so our country attaches great importance to the textile industry. In the textile industry, beam is an indispensable part of the entire textile process.

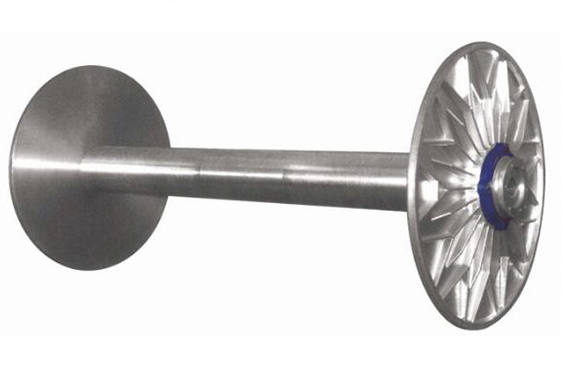

The construction of the beams is not complicated, in simple terms, it consists of two parts: the beam flange and the roller, let’s see some pictures for better understanding:

Generally speaking, in the textile industry, beams can be divided into weaving beams and warp beams. First of all, let's take a look at what are weaving beams and warp beams. So how is the weaving beams formed? The paddle shaft and the warp beam are processed through the heald reed to obtain the weaving beams. That’s what we called weaving beams. What about warp beams? Warp beam, a horizontal axis used to fix the warp threads during spinning, so that the warp threads are arranged in a certain order and interval. In summary, we have a preliminary understanding of the definition of weaving beam and warp beam.

Let’s see the appearance of them:

So next, we can take a look at how they work during the production process. In the weaving process, we can roughly divide it into five steps: Winding, Warping, Sizing, Drawing-in and Weaving. Winding (also known as winding) is the first process of preparation before weaving. Its task is to process the cop or skein from the spinning department into a package that meets certain requirements on the winder. Warping is the process of winding a certain number of warp yarns in parallel on the warp beam or weaving shaft according to the specified length and width. Warp yarns that have been warped are used for sizing and threading. Warping requires that the tension of each warp yarn is equal, evenly distributed on the warp beam or weaving shaft, and the arrangement of colored yarns conforms to the process regulations. Sizing The process of applying sizing to warp yarns to improve their weaveability. Weavability refers to the ability of warp yarn to withstand repeated friction, stretching, bending, etc. on the loom without causing a lot of fluff or even breakage. The unsized single yarn fibers are not tightly attached to each other, and the surface hairiness is more, making it difficult to weave. After sizing, a part of the sizing liquid penetrates between the fibers, and the other part adheres to the surface of the warp yarn. The sizing based on the penetration of the sizing between the fibers is called permeable sizing, and the sizing based on the sizing sticking to the surface of the warp yarn is called covering sizing. Draw-in Each warp thread is passed through the heddle eyelet in the sequence required by the process to realize the upper and lower opening and closing movement of different warp threads. Different fabrics have different stitching methods, which together with the stitching method determine the fabric's organizational structure. The same fabric can also have different drawing methods in consideration of weaving and weaving efficiency. Weaving is to make the warp and weft yarns show specific patterns according to certain rules according to the weaving design organization chart provided by the fabric designer. The movement of the warp yarn is completed by the up and down movement of the brown frame, and the left and right movement of the weft yarn makes it have a certain organizational structure and form a specific pattern.

Warp Beam is suitable for spun and filament yarn. Benninger, Karl mayer, Hakoba, West Point, Suker and other high speed sectional and conventional warping machines. Available Size: 800mm flange diameter to 1400mm dia. Working width: 1600mm to 2800mm. Weaving Beam is applicable for Toyota, Tsudakoma, Picanol, Sulzer, Dornier and other air jet, water jet, rapier and projectile high speed looms in single section and double section construction with or without differential motion up to 1250mm flange diameter and 540cm working width.

Below are the package of beams, usually they will be packed separately: