The modernization of textile machinery has significantly transformed textile production and finishing, benefiting both developed and some developing nations. This rapid expansion has not only advanced textile machinery technology but also accelerated the development of new fibers, industrial textile raw materials, chemical fibers, and processing techniques. The textile industry is now closely integrated with the garment sector, driven by specialized machinery requirements. This demand propels the overall progress of the industry.

The Indian Textile Sector's Resurgence

In recent years, India's textile sector has experienced a remarkable resurgence, especially benefiting the textile machinery industry, notably in spinning and weaving. From October 2009 to September 2010, textile machinery production in India increased by an impressive 52% over the previous year. The spinning and weaving sectors saw machinery production surge by a staggering 72% during this period, driven by a robust domestic economy post-economic crisis.

Despite challenges like rising raw material costs, such as cotton and polyester, the industry has adeptly passed these costs to end users. The Indian government's Technology Upgradation Fund Scheme (TUFS) has significantly supported the industry, encouraging many textile companies to upgrade their machinery. By June 2010, around 2.82 billion rupees were allocated for fiscal year 2011 to further advance the textile machinery sector.

The Importance of Cotton Textiles

Cotton textiles hold a prominent place in India's textile exports, comprising nearly 50% (valued at 5.08 billion dollars). In 2008, global trade in cotton textiles grew by approximately 4%, surpassing the 3.70% growth of other fiber textiles, indicating a rising international preference for cotton fabrics.

Post-Quota Era and Global Competitiveness

The post-quota era has transformed global sourcing in the textile industry, with competitiveness now hinging on cost-effectiveness, quality, and timely delivery. The Indian textile industry's journey in adapting to these international trade dynamics has been mixed. The development within the industry has been uneven, with the spinning sector being more organized than the fragmented weaving sector. The organized segment dominates over 80% of the spinning industry but less than 5% of the weaving sector, where many medium-sized factories form consortia.

Challenges and Progress

Over the past few decades, the textile industry has made significant strides in overcoming challenges related to outdated technology, raw material availability, and the need for modernization, particularly in the spinning sector. However, compared to key competitors, the weaving and processing sectors remain weak links, primarily supported by small and medium-sized enterprises.

Improvements in textile technology, dyeing, processing, and finishing capabilities have been noted, yet there is still considerable progress to be made to match neighboring countries. India's clothing industry comprises over 25,000 domestic manufacturers, 48,000 processing units, and around 4,000 manufacturers/exporters, with more than 80% being small-scale enterprises with fewer than 20 machines.

Conclusion

India's textile industry, with its significant advancements and challenges, continues to evolve. The sector's competitiveness on the global stage relies on ongoing modernization, strategic government support, and the industry's adaptability to international market demands. Despite its fragmented structure, the potential for growth and leadership in the global textile market remains strong.

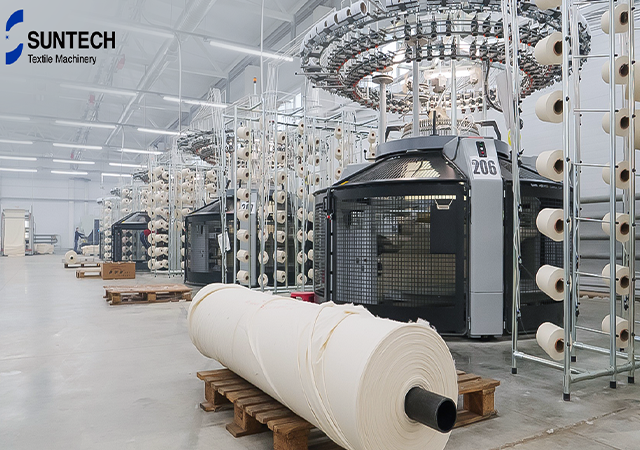

SUNTECH has experienced over 50 years in the textile machinery industry, and is doing the utmost to innovate and study and realized the strict requirements of the textile machinery such as fabric sample cutting machine, automatic packaging machine. SUNTECH never stop innovation and welcome to inquiry.