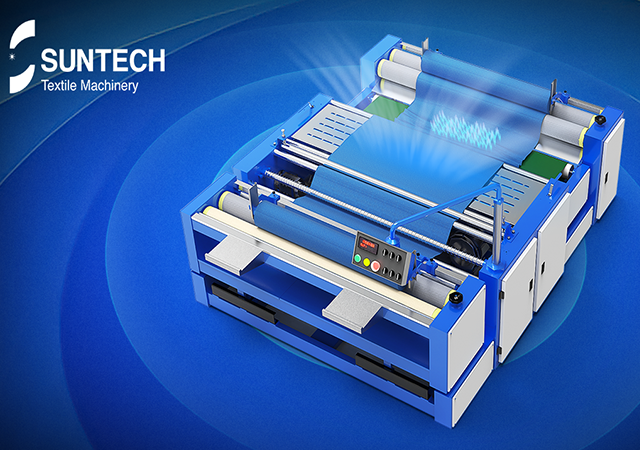

SUNTECH Textile Machinery Upgraded Roll-to-Roll Fabric Relaxing Machine (5th Generation) stands at the forefront of technological advancements in fabric handling and relaxation. This upgraded model transcends industry norms, boasting an array of advanced features and functionalities that set it apart.

1.Basic Functions of this upgraded Roll-to-Roll Fabric Relaxing Machine

lTension-Free Fabric Feeding: The machine deftly unwinds fabric from two motor-driven rollers and inverters, ensuring a seamless feed devoid of any tension-inducing disruptions.

lAir-Flotation Zone: Equipped with an air-flotation zone, the machine orchestrates comprehensive fabric relaxation, effectively reducing processing time.

Vibrating Conveyor: As the fabric reaches the air duct on the conveyor belt, the synchronized motion of the vibrating table and the gentle airflow collaborate harmoniously to delicately shake the fabric, ensuring the complete eradication of any residual tension.

lCompatible Output Fabric Roll: The machine generates a relaxed fabric roll that seamlessly integrates with automatic spreading machines, thereby streamlining subsequent processes and yielding notable time and space savings.

lAutomatic Edge-Alignment System: With its built-in Automatic Edge-Alignment System, the machine maintains edge-alignment errors well below 6mm, ensuring unparalleled precision and accuracy in fabric alignment.

lAccurate Length Counting: The machine boasts dependable length counting capabilities in both yards and meters, minimizing counting errors to a mere 0.1m/km.

lOptional Automatic Width Measuring Device: For online measurements, an optional Automatic Width Measuring Device is available, delivering enhanced accuracy and unmatched convenience.

lAutomatic Weight Device: Empowered by an Automatic Weight Device, the machine allows for precise measurement of fabric weights ranging from 1000-2000kgs, bolstering operational efficiency.

2.Combining With ST-Thinkor(AI Automated Visual Inspection System)

SUNTECH fabric relaxing machine can be seamlessly integrated with the revolutionary AI automated visual inspection system. By affixing the AI fabric inspection system onto the fabric relaxing machine, the meticulously tension-released fabric rolls can be effortlessly fed directly into the fabric cutting machine.

This harmonious amalgamation engenders a fully automated production process, encompassing meticulous fabric inspection, precise tension release, and seamless cutting, thereby endowing clothing factories with an impeccable, streamlined, and highly proficient solution.

SUNTECH Textile Machinery is dedicated to providing the garment industry and garment factories with intelligent and efficient fabric rolls handling solutions, addressing the challenges posed by high order pressures and stringent requirements for fabric inspection, fabric relaxation, and fabric cutting.

Fabric relaxation is a critical step in the textile industry to ensure optimal performance and appearance of various fabrics. Typically, customers have had to wait for 6 to 24 hours using normal or manual relaxing methods before cutting the fabric.

Our machine boasts unparalleled efficiency, allowing most customers to cut the fabric immediately after relaxing it, eliminating the tedious laying time. Whether it's elastic knitted fabric, woven fabric with spandex, or even denim, our Roll to Roll Fabric Relaxing Machine can handle them all with ease.

We understand that fabric relaxation performance is of utmost concern to our customers. Therefore, we offer the option to strengthen the air blowing motor, enabling even more efficient fabric relaxation. While this enhancement might come with an additional cost, it ensures that your fabrics are perfectly relaxed and ready for use.

The main function of our machine is to significantly reduce the fabric laying time, and rest assured, you'll experience a fabric relaxation performance similar to what you'd achieve with a 24-hour manual relaxing method.

SUNTECH fabric relaxing machines are shipped as complete units, meaning there's no need to fret about complex installation procedures. You'll only need to find an engineer to handle the straightforward installation process, following the circuit diagram provided, and your machine will be ready to operate seamlessly.

Invest in our Roll to Roll Fabric Relaxing Machine today and experience a new level of fabric relaxation efficiency, saving you time, effort, and resources. Say goodbye to long waiting times and hello to enhanced productivity and fabric quality. Contact us now to discover how our machine can revolutionize your fabric relaxation process!