Rapier weaving machine in China, from the primitive looms that appeared 7000 years ago, to the pedal looms and multi-heddle jacquard looms that appeared in large numbers in the Qin and Han Dynasties of the Warring States Period (200 BC - 200 BC), they have reached the highest level of looms in the world.

The earliest rapier weaving machine was the squat loom (called the waist loom) that sat on the ground. After the weaving technology exchange on the Silk Road, in the early Tang Dynasty (700 years), the real beam-heddle jacquard machine appeared in China, and it took the lead in the Song, Yuan, Ming and Qing dynasties. So far, China has not only unearthed important models of jacquard machines in the Han Dynasty in archaeology, but also has "Chinese sericulture and silk weaving skills" included in the representative list of human intangible cultural heritage. Not only are a large number of jacquard looms popular in the Han area, but there are also a large number of different types of looms left in the minority, which are the crystallization of ancient Chinese human wisdom. The early looms in China are generally called primitive waist looms. When weaving, the weaver sits on the ground, uses the body as a frame, pushes on the warp beam with both feet, ties the cloth winding shaft around the waist, carries the heald, forms the shed, and then picks and beats the weft to weave the fabric.

The common basic feature of rapier weaving machine is to separate the weft yarn package from the shuttle, or to carry only a small amount of weft yarn to replace the large and heavy shuttle with a small and light weft inserter, which provides favorable conditions for high-speed weft insertion. . In the supply of weft yarn, the bobbin package is directly used, and it enters the weft insertion mechanism through the weft storage device, so that the loom can get rid of the frequent weft replenishment action.

The use of rapier weaving machine is of great significance for increasing fabric varieties, adjusting fabric structure, reducing fabric defects, improving fabric quality, reducing noise and improving working conditions. The speed of shuttleless looms is high, and the efficiency is usually 4-8 times higher than that of shuttle looms. Therefore, the application of shuttleless looms in a large area can greatly improve labor productivity.

As the structure of the rapier weaving machine is improving day by day, and the selection of materials is wide, and the processing accuracy is getting higher and higher, coupled with the development of science and technology in the world, the electronic technology and microelectronic control technology gradually replace the mechanical technology, rapier weaving machine manufacture is a high-tech product that combines metallurgy, machinery, electronics, chemical industry and fluid power and other disciplines, and integrates electronic technology, computer technology, precision machinery technology and textile technology.

The air-jet loom detects the total warp tension through the tension sensor, and the CPU controls the warp tension changes caused by the opening, warp loosening, let-off, and warp diameter changes, so as to ensure the warp let-off accuracy and maintain a constant warp tension. Because the air-jet loom adopts microcomputer technology and other electronic technologies to control the movement of the whole machine, especially the automatic monitoring of product quality, the production efficiency of the air-jet loom is greatly improved. At the same time, air-jet looms have higher and higher requirements for the electronic control system, which not only must have high performance, good stability, easy maintenance, and low failure rate, but also must be able to adapt to the environment of high temperature, high humidity, high hairiness and dust. It also has strong anti-interference requirements for power supply fluctuations and group interference.

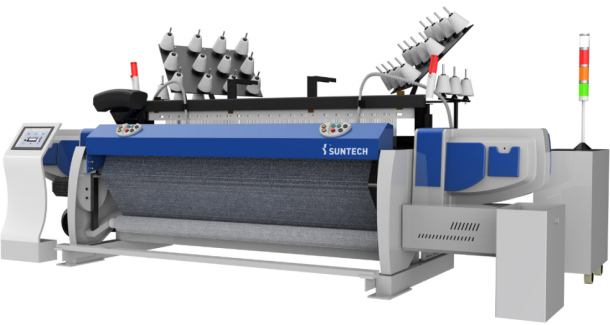

Since we have known well about the rapier weaving machine, you must be interested about it. To know more details about the rapier weaving machine, please view our Suntech’s official website: https://www.suntech-machine.com/. We have many types of rapier weaving machine, please keep us in touch if you want to order rapier weaving machine.