In printing, dyeing, textile and other industries, it is often necessary to fold the fabric in half horizontally (for example, a fabric with a width of 3200mm is folded into 1600mm), and then fabrics be rewound on paper tube or paper board to a certain length, by this way, it’s more convenient for storage and transportation turnover. As for a folding machine, the basic requirement is fabric edges be aligned well after folding, meanwhile,the cloth cannot be wrinkled after folding in half. Some Chinese manufacturers began to produce folding machines in the 1990s, the fabric folding machine price is related to the production capacity.

Suntech is able to provide difference kinds of folding machine, we recommend the suitable machine according to customer’s requirement. We have our own factory, that’s why our fabric folding machine price is more competitive than other suppliers’ machine.

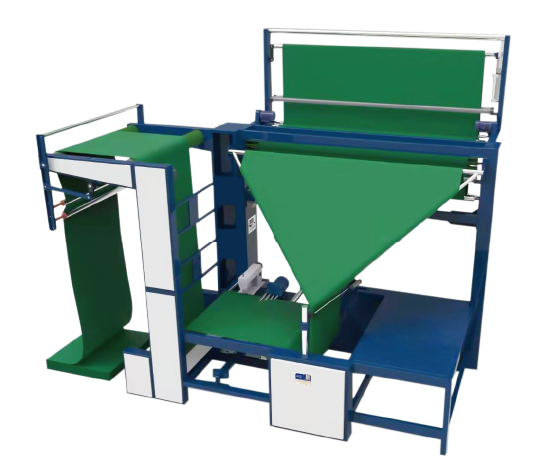

SUNTECH DOUBLE FOLDING MACHINE

Now the commonly used method of fabric folding in half is shown in the figure: the fabric enters the tripod in the direction of the arrow in the figure, and after the fabric is folded in half by the tripod, the edge-aligning detection device detects the two edges of the fabric, and the edge-aligning adjustment rod is driven by pneumatic or hydraulic. Correct the uneven selvedge. The tripod is fixed by the first fixed point, the second fixed point and the third fixed point. The length of the adjusting strut where the third fixed point is located can be adjusted to adjust the included angle, so that the included angle can reach a suitable angle and realize the fabric Flat and wrinkle-free after folding in half.

(1) The cloth guider at the inlet position will make the fabric in the center of the machine. Once it runs deviation, the cloth guider will correct it immediately.

(2)Adjust the Triangle Frame as per the actual situation.

(3) Adjust the Edge-alignment Photo Sensor along with the Fabric Limited Bar, make sure the photo sensor could detect the fabric edges.

(4) When feeding the fabric manually, make sure the two edges of fabric has been double folded very well. The edge-alignment error is less than 6mm.

However, in the process of mass production, the variety and quality of fabrics often change. In many cases, even the same batch of fabrics of the same variety will have irregular loose edges or tight edges due to changes in production and setting processes. situation. At this time, in the case of the included angle A, if the fabric has loose edges, when the fabric comes out of the tripod, due to the loose edges of the fabric, the rectifying effect of the edge-aligning lever is weakened, and it is not easy to align the edges. If the fabric has a tight edge, the fabric at the sharp corners of the tripod will have serious wrinkling problems.

SUNTECH DOUBLE FOLDING AND SEWING MACHINE

For sewing, actually it is single-thread sewing. We purchased the JUKI Sewing Machine(Model DDL-8700) and modified on its base. The original sewing machine can not work well in this application. Once the dyeing is finished, the operator just needs to pull the thread and the tubular fabric will come into open width again. It is very easy.

1.)There is one pneumatic deviation roller at fabric entry, the photo-sensor will detect if the fabric is in middle of machine, and will send signal to move deviation roller up and down to move the fabric in middle of this machine.

2)there is a big centering roller, will make the fabric in center of machine before folding.