The current instability in Bangladesh has led to a cautious approach among buyers, with many hesitant to place new orders. This has created a projected gap of 10% to 15% in order volumes for the upcoming season. To address this challenge, apparel manufacturers in Bangladesh are taking strategic steps to strengthen relationships with buyers and maintain their status as a reliable supplier in the global market.

Direct Engagement with Buyers to Build Confidence

Understanding the importance of direct engagement, Bangladeshi manufacturers are visiting key markets to meet with buyers personally. These visits serve as more than routine business interactions; they are strategic initiatives aimed at reassuring buyers of the industry's commitment to fulfilling orders on time and maintaining high standards of quality, despite the challenges posed by political instability and supply chain disruptions.

Through these in-person meetings, manufacturers can provide buyers with first-hand updates on their production capabilities, ongoing product developments, and the measures being implemented to ensure the continuity of supply chains. This direct communication is essential for building trust and instilling confidence among buyers, which is crucial in securing orders in a competitive global market.

Enhancing Marketing Efforts and Communication

In addition to direct engagement, there is a strong emphasis on enhancing communication through digital marketing, email campaigns, and virtual meetings. These efforts aim to keep buyers informed about the latest industry developments, showcasing Bangladesh’s resilience and adaptability in the face of adversity.

Marketing strategies are also being refined to highlight the strengths of Bangladesh’s apparel industry, including its commitment to sustainability, ethical manufacturing, and innovative product design. By focusing on these areas, manufacturers seek to differentiate themselves from competitors and appeal to buyers who prioritize these values in their sourcing decisions.

Forging Long-Term Partnerships

Beyond immediate reassurance, Bangladeshi manufacturers are working to establish long-term partnerships with buyers. This involves not only meeting current demands but also collaborating on future projects, product innovations, and supply chain improvements. By positioning themselves as strategic partners, rather than just suppliers, manufacturers can create more sustainable and mutually beneficial relationships.

Leveraging New Leadership for Industry Growth

Amidst these challenges, the leadership of Dr. Muhammad Yunus offers a sense of optimism and stability to Bangladesh's apparel industry. With his global reputation as a visionary leader and social entrepreneur, Dr. Yunus is well-positioned to enhance the industry's image and effectively address current issues. Manufacturers are encouraged to brand this new leadership to further solidify their position in the global market.

Navigating Challenges and Preparing for Future Growth

In a challenging global environment, Bangladesh's apparel industry is taking decisive steps to manage the current order gap while laying the groundwork for future growth and recovery. These efforts are crucial for maintaining the industry’s reputation as a reliable supplier and for building stronger, more resilient relationships with global buyers.

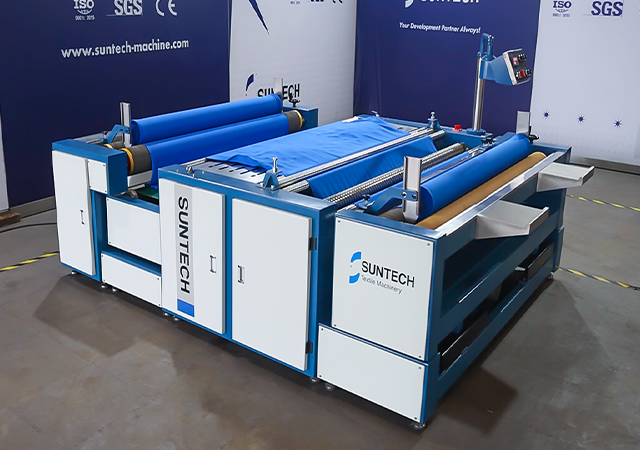

The Role of Fabric Relaxing Machines in Garment Manufacturing

Fabric relaxing machines are vital tools in the garment manufacturing process, offering several benefits to manufacturers. These machines help improve the quality of finished garments by ensuring the fabric is free from tension and distortion. Additionally, they increase production efficiency by reducing the risk of fabric defects and minimizing the need for rework or adjustments. The use of fabric relaxing machines also ensures consistency in the production process, resulting in fabrics with uniform properties and dimensions.

Types of Fabric Relaxing Machines

Various types of fabric relaxing machines are available, including open-width relaxing machines, rope relaxing machines, and batch relaxing machines. Open-width relaxing machines are ideal for flat fabrics, while rope relaxing machines are suited for tubular fabrics. Batch relaxing machines are designed for relaxing fabrics in large quantities.

The Critical Role of Fabric Relaxation Machines

Fabric relaxing machines are essential for ensuring high-quality garment production. By eliminating tension and distortion in fabrics, these machines contribute to the consistency and efficiency of the manufacturing process. As the textile industry continues to evolve, the importance of fabric relaxation machines in producing high-quality garments will only grow.