Textile industry, closely involved in everyone’s daily life, is of great significance not only in China, but also in countries all over the world. For years, because of its huge system, textile industry is one of pillar industry in many countries, especially developing countries. Nowadays, rapid technical innovation brings about great changes for textile industry. Digital applications have entered textile industry gradually and automatic production becomes a trend. However, there is still plenty of room to improve storage system. And intelligent beam storage system will definitely play a big role in textile industry.

Problem and Solution of Textile Industry

With the rapid development of science and technology since the first Industrial Revolution, textile industry, closely related to our daily life, has undergone earth-shaking changes.

Textile is a systematic process, including chemical fiber, spinning, manufacturing, printing and dyeing. Under the background of intelligent manufacturing, China's textile industry has begun to automate. However, some process like packaging and storage still relies on manual labor.

Therefore, the solution to improve the efficiency of distribution and storage is of vital importance. The intelligence of storage system plays an important role in improving the efficiency of the supply chain, shortening the material distribution and circulation cycle, and accelerating the speed of market response. It is also regarded as one of the core copetitiveness of more and more enterprises in the future.

SUNTECH Beam Storage System(Beam Stackers)

SUNTECH, as a leading Weaving Machine manufacturer, with 50 years of research and development, tries to improve production efficiency through intelligent equipment, which greatly reduce labor costs. SUNTECH provides the most advanced solutions for automatic loom, weaving machine, rapier loom, etc.

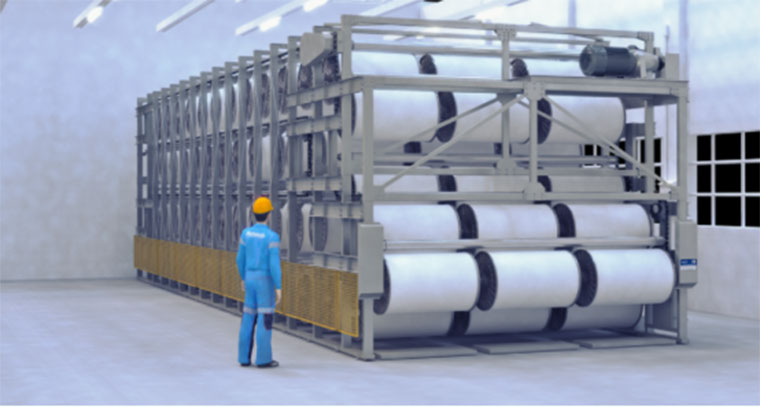

SUNTECH beam stackers, using digital monitoring, automatic classification management and storage of the Warp beam can be realized. Thus it helps find and retrieve the required Warp beam more quickly and accurately. In addition, Warp beam lift trolley is highly recommended to be used together with beam stacker, which is suitable for Bottom Bean transporting. The specific description of this two products showed at below.

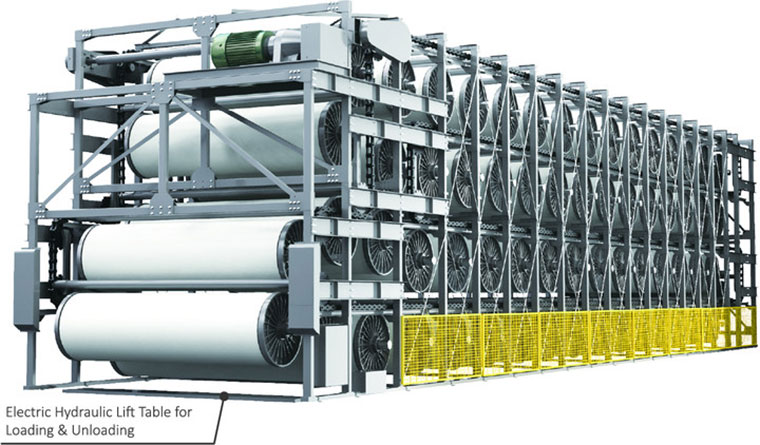

Computerized Warp Beam Storage System

For the storage of warp, size, weaving and cloth beam, Computerized Warp Beam Storage System is absolutely the best solution. It is applied in the weaving preparation workshop and weaving unit, as well as finishing unit for space utilization widely, which can also avoid damage from ready warp and cloth beam.

It is available to handle each particular situation in different models. For instance, you can load and unload from one location to one or multiple locations at different levels.

Key Features

1. Intelligence, reduce labor cost and improve efficiency.

2. Sequential control of machine is enclosed by control panel with PLC.

3. Touch Screen Operation, easy and quick access of data or machine operation through HMI (Touch Panel).

4. Customizable language, different language is provided.

5. Can be controlled by mobile phone.

6. ERP system can be connected.

7. Double guarantee for the hanging scroll is provided by safety hanging chain.

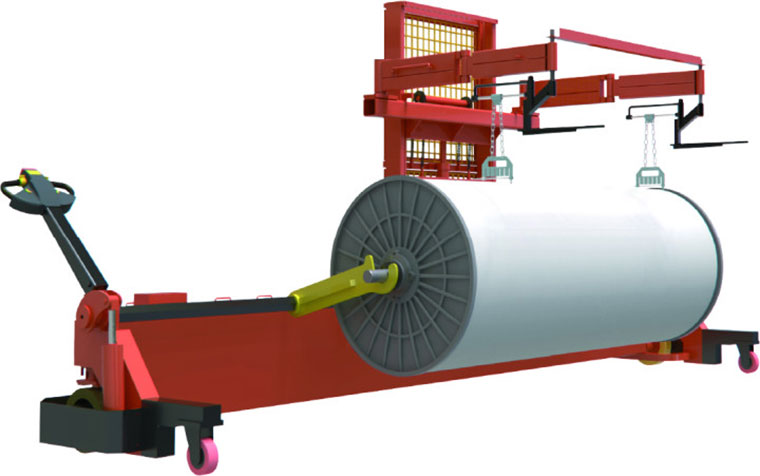

Motorized Warp Beam Lift Trolley with Harness Mounting Device

Motorized Warp Beam Lift Trolley System is suitable for Bottom Beam transporting, using harness mounting device and insert in weaving machines.

Warp beam weigh up to 2500kg and an additional loading capacity of 400 kg for the harness, meeting with European CE standard, certificate is available. Furthermore, the warranty extension is provided.

SUNTECH only produces high quality products and always pursues intelligence and automation. Anyone interested in SUNTECH beam stacker could visit our website to obtain more detailed information. We are always ready to be your reliable and eternal partner.